41 - 50 of 244

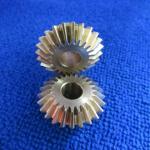

precise torque transmission bevel gear

Selling leads|

...designed to minimize backlash, ensure precise motion transmission, and maintain consistent performance over extended periods. High precision gears ...

2024-12-09 19:39:07

|

|

...gear are straight (straight) and the size of the gear gradually changes along the axis (taper). 2. The characteristic of straight bevel gears is ...

2024-12-09 20:19:24

|

|

...transmit the power of the chain to the rear wheel. Because bevel gears can mesh at an angle, they effectively convert the linear motion of the ...

2024-12-09 21:42:08

|

|

...Bevel Gear Grinding Finished Smooth Transmission For Power Tool The driving bevel gear is used as a power input component in the mechanical ...

2025-07-21 00:28:01

|

|

...tighter meshing, which reduces energy loss and frictional resistance during the transmission process, thereby improving transmission efficiency. 2. ...

2024-12-09 19:39:07

|

|

... design. In this gear system, the axes of the two gears are perpendicular to each other, that is, the axis intersection angle is 90°. This design ...

2024-12-09 20:19:24

|

|

...tem, especially for changing the transmission direction and speed ratio. Here are some specific application details: Changing the direction of ...

2025-07-21 00:28:01

|

|

...Bevel Gear for Motor Drive Part with 20 Degree Pressure Angle 40Cr spiral bevel gear with 20-degree pressure angle is a mechanical transmission ...

2024-12-09 20:04:16

|

|

... and reduce operating vibration and noise. Helical gears have high transmission efficiency. Helical gears have a large number of gear teeth, large ...

2024-12-09 20:04:16

|

|

... mechanism (the two shafts form a certain angle, usually 90° perpendicular). In the 180 polisher, they undertake two core tasks: 1.Direction - ...

2025-07-21 00:28:01

|