41 - 50 of 209

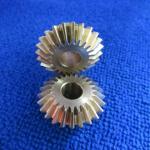

high precision hypoid bevel gear

Selling leads|

...Bevel Gear Spiral Reduction Gear with Cutting, Turning, Grinding Process Arc bevel gear reduction gear has the following characteristics: 1.High ...

2025-07-25 00:24:21

|

|

... processing: Rough machining of the gear blank, cutting off excess material, and initially forming the shape and size of the gear. 2. Heat ...

2025-07-25 00:24:21

|

|

...-bearing capacity. They can withstand large loads and impact forces under harsh working conditions, ensuring the stability and reliability of the ...

2024-12-09 19:39:07

|

|

...designed to minimize backlash, ensure precise motion transmission, and maintain consistent performance over extended periods. High precision gears ...

2024-12-09 19:39:07

|

|

...Bevel Gear Straight Gear With 90 Degree, Quenching And CNC Precision Turning 1. Straight bevel gears are commonly used in a variety of mechanical ...

2024-12-09 20:04:16

|

|

...Gear (Zero Bevel Gear) for Wind Turbines, Ship Propulsion Systems 1. Compared with ordinary helical gears, the two tooth surfaces of zero-bevel ...

2024-12-09 19:39:07

|

|

.... The transmission process is smooth, the structure is compact, the operation is reliable, and it can save space. The wear resistance life is ...

2025-03-31 15:31:55

|

|

... produced in a closed-loop system to ensure the high precision of production. Products High Reduction ratio Quasi-Hyperbolic Gear Grinding Service ...

2024-12-09 19:39:07

|

|

... and reduce operating vibration and noise. Helical gears have high transmission efficiency. Helical gears have a large number of gear teeth, large ...

2024-12-09 20:04:16

|

|

Product: Carburzing and Quenching Ground Helical Bevel Gear with High Precision 1. The manufacturing of ground spiral bevel gears requires the use of ...

2025-07-25 00:24:21

|