71 - 80 of 192

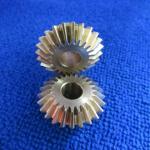

helical grinding gears

Selling leads|

...gear? Gears are mechanical parts with teeth that mesh with each other. It is widely used in mechanical transmission and the entire machinery field. ...

2025-03-19 23:29:36

|

|

DIN 6- DIN 8 Helical Gear Straight Gear Rack with Milling, Grinding & Quenching About rack? There are many types of racks, and different rack ...

2024-12-09 20:04:16

|

|

... gear transmission. Therefore, staggered helical gear transmission is used to transmit motion and power between two staggered axes in space. The ...

2024-12-09 19:39:07

|

|

... on the gear tooth surface in order to achieve the goals of improving gear accuracy, improving surface quality, and reducing noise. The application...

2024-12-09 21:45:58

|

|

... gear shaft connects the helical gears and is fixed in the transmission by bearings. Helical gear is a cylindrical gear with a cylindrical helical ...

2024-12-09 21:47:21

|

|

... change through complex gear transmission mechanisms. High-end planetary reducer generally adopts high precision helical gear, there will be ...

2024-12-09 21:45:58

|

|

...Helical Gear Circular-Arc Gear Reducing Noise And Vibration For Ovearall Performance Helical gears are a type of cylindrical gear that have angled ...

2024-12-09 19:39:07

|

|

... and reduce operating vibration and noise. Helical gears have high transmission efficiency. Helical gears have a large number of gear teeth, large ...

2024-12-09 20:04:16

|

|

...resistance. Gear teeth are inclined to both sides, and there are two directions of transmission: forward and reverse. What are the characteristics ...

2024-12-09 20:04:16

|

|

... produced in a closed-loop system to ensure the high precision of production. Products High Reduction ratio Quasi-Hyperbolic Gear Grinding Service ...

2024-12-09 19:39:07

|