Irb 6700 Datasheet Robotic Arm Purchase Robots In Manufacturing

|

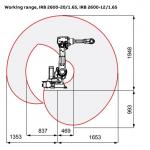

Irb 6700 Datasheet Robotic Arm Purchase Robots Used In ManufacturingThe ABB IRB 6700 is a heavy-duty industrial robot designed for high-performance automation in welding, material handling, and assembly applications. With its six-axis flexibility, robust construction, and advanced motion control, the IRB 6700 is a top choice for industries requiring precision, speed, and reliability. Key Features of the ABB IRB 6700 Six-Axis Robot1. High Payload Capacity (150-300 kg)The IRB 6700 is built for heavy-duty applications, offering payload capacities ranging from 150 kg to 300 kg, making it ideal for large-part welding and material handling. 2. Extended Reach (2.6m - 3.2m)With a reach of up to 3.2 meters, this robot can handle large workpieces, reducing the need for repositioning and improving efficiency in welding and assembly lines. 3. Advanced Six-Axis FlexibilityThe six-axis articulation allows for complex welding paths, enabling precise movements in tight spaces—perfect for automotive, aerospace, and heavy machinery welding. 4. Optimized for Welding ApplicationsABB’s welding database for the IRB 6700 includes pre-programmed settings for various welding processes (MIG, MAG, TIG, spot welding), ensuring consistent weld quality and reducing setup time. 5. Energy Efficiency & Reduced DowntimeABB’s OmniCore™ controller enhances energy efficiency by up to 20%, while predictive maintenance features minimize unplanned downtime. 6. Robust & Durable DesignBuilt for 24/7 operation, the IRB 6700 features IP67 protection (dust and water-resistant), making it suitable for harsh industrial environments. ABB IRB 6700 Welding Database: Enhancing Automation EfficiencyThe ABB IRB 6700 welding database is a key asset for manufacturers, offering:

This database reduces programming time and ensures high repeatability, making it ideal for high-volume production. Applications of the ABB IRB 6700 in Industrial RoboticsThe IRB 6700 excels in: ✅ Automotive Welding – Body-in-white, chassis, and component welding Why Choose the ABB IRB 6700 for Industrial Welding?✔ Superior precision & repeatability for high-quality welds Advantage

FAQ: *Q:Why are we? A:Our company works robot industry over fifteen years. Programming robot inclusive KUKA ,ABB,YASKAWA,FANUC,ESTUN(Chinese ROBOT ),EFORT(Chinese robot). the business involved simulation,programming,service after warranty period. *Q:How about our service concept? A:We keep on phone open all day. Stand in customer view to provide rationalization solution and robot selection. *Q:What products can we offer? A:robot, energy supply for robot, linear for robot. Training for robot. Gripper for handling. *Q:Why you purchase from us? A:You don’t worry about after-sales problem to cooperation with us. About us Companies in the "customer first, quality first, the user first" purpose, we will as always Warm and sincere service for all users, friends and customers, create brilliant tomorrow. Our main customers are Baosteel, INO,Volkswagen,Geely and so on. Over fifteen years experience in the robot industry. Our engineers can design solution,simulation,program and troubleshooting. So if you have any issue of robot. Call us any time. We will try our best to solve the problem. The other advantage is after-sales service,we have robot spare parts in stockroom. We can response promptly to help you resolve robot fault. We also have robot training. The course include programming, electric, mechanic and expert programming. So welcome to join our college. |

||||||||

| Product Tags: Irb 6700 Datasheet Robotic Arm 6 Axis Robotic Arm |

|

Irb 6700 Datasheet Robotic Arm Purchase Robots In Manufacturing |

|

Abb Irc5 IRB 660/250 High-performance Industrial Robot Manufacturing |

|

Robot Assembly Line Abb Arms 660/180 Supply Industrial Machine |

|

2600/20 Irb 2600 Robotic Spray Painting System High-speed Industrial Robotic |

|

Irb 2600 Industrial Robotic Arm Optimized For Short Beat Times |

|

Abb Irb 6700 Six Axes Welding Database Heavy-Duty Industrial Robotics |