Kuka Robot Programming KR 20 Automatically Stack Goods Industrial Robotic Arm

|

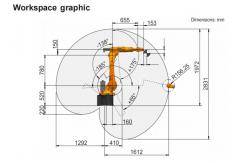

Kuka Robot Programming KR 20 Automatically Stack Goods Industrial Robotic ArmThe KUKA KR 20 is a high-performance industrial robotic arm designed for automated stacking, palletizing, and material handling. With its 20kg payload capacity, six-axis flexibility, and precision programming, this robot streamlines logistics, warehousing, and production line operations. Key Features of the KUKA KR 20 Industrial Robot✔ 20kg Payload Capacity – Handles medium-weight stacking tasks efficiently. Why Choose the KR 20 for Automated Stacking & Palletizing?

Best Applications for the KUKA KR 20

KUKA Robot Programming for Stacking & PalletizingThe KR 20 can be programmed for: Advantage:

Place of origin: China Brand Name: KUKA Model Number: KR 20 R1810-2

FAQ: *Q:Why are we? A:Our company works robot industry over fifteen years. Programming robot inclusive KUKA ,ABB,YASKAWA,FANUC,ESTUN(Chinese ROBOT ),EFORT(Chinese robot). the business involved simulation,programming,service after warranty period. *Q:How about our service concept? A:We keep on phone open all day. Stand in customer view to provide rationalization solution and robot selection. *Q:What products can we offer? A:robot, energy supply for robot, linear for robot. Training for robot. Gripper for handling. *Q:Why you purchase from us? A:You don’t worry about after-sales problem to cooperation with us. About us Companies in the "customer first, quality first, the user first" purpose, we will as always Warm and sincere service for all users, friends and customers, create brilliant tomorrow. Our main customers are Baosteel, INO,Volkswagen,Geely and so on. Over fifteen years experience in the robot industry. Our engineers can design solution,simulation,program and troubleshooting. So if you have any issue of robot. Call us any time. We will try our best to solve the problem. The other advantage is after-sales service,we have robot spare parts in stockroom. We can response promptly to help you resolve robot fault. We also have robot training. The course include programming, electric, mechanic and expert programming. So welcome to join our college. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Storage Efficiency Robots |

|

Kuka Kr 180-2 Pa 5 Axes Industrial Robot Material Handling |

|

Kuka Laser Welding KR 20 KUKA.SimPro Offline Programming Software |

|

Kuka Machine 6 Axis Robot Arm R KR 210 Robotic Arm Welding |

|

Kr Quantec Pa KR 240 R3200 PA 5-axis Palletizing Automation Robot Arm |

|

Kr16 R2010 Kuka Lightweight Robot Six-axis Industrial Robot |

|

Kuka Kr 150 R3100 Prime Robotics Systems Integrators Industrial Robot |