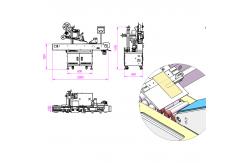

Reagent tube printing and labeling machine Suitable for labeling various small-sized cylindrical and conical

products, such as like diagnostic reagent, detection reagent, vaccine etc cosmetic round bottles, small medicine

bottles, plastic bottles, PET round bottles 502 glue bottle

labeling,oral liquid bottle labeling, pen holder labeling, lipstick

labeling,and other small round bottles etc. It is widely used in

round bottle labeling in food, cosmetics, wine making, medicine,

beverage, chemical industry and other industries, and can realize

full product coverage labeling labeling. Printer type: TCC | TSC-PEX-1100 | Printing type: | Thermal transfer/thermal | Print resolution : | 600dip | Print size: | Width 25- 104mm; Length 25-250mm | Induction mode : | Gap induction (transmissive), reflective | Label material: | Coated Paper, Synthetic Paper, Glassindy | Roll size: | ID Φ76mm OD 300mm | Label size: | Width 25.4-116mm;Thin: 0.06-0.30mm | Carbon ribbon : | Width 25-110mm; Lenth 450 m,MAX OD 90mm , When winding the

ribbon,Coated side outward | Interface: | R232 serial port / Parallel parallel port/ USB2.0 internet access | Label type: | Flat surface | Printing content: | Text, serial number, date, pattern, one (two-dimensional) barcode

and other identification | Accuracy: | ±1mm | Speed(pcs/min) | 30~80pcs/ min | Label size(L×W)mm | (20-180mm) ×(20mm-100mm) | Object size | OD:15.4mm,L:10.4mm--OD:24mm,L:10.2mm | Roll OD | Φ300mm | Roll ID | φ76mm | Weight(kg) | 120kg | Voltage(V) | 220V | Power(W) | 600W | Machine size(L×W×H) (mm) | 2000×800×1450mm |

Additional functions to increase options① Optional automatic rotary bottling machine.

② It can be directly connected to the production line to realize

automatic bottling and improve production efficiency.

③ The optional ribbon coding machine can be added to the label

head, and the production batch, production date and expiration date

can be printed at the same time. Reduce packaging procedures and

greatly improve production efficiency.

④ Automatic feeding function (combined with product consideration);

⑤ Automatic material collection function (combined with product

consideration);

⑥ Increase labeling device; Working processworking principle: The PLC processes product signal and label

signal, then outputs signal to the traction motor to start

labeling.

Labeling Process: Put products in the feeding device→ The products

are separated one by one → The products are transmitted by the

conveyor belt → The product sensor detects the product→ PLC

receives the product signal and start labeling→ the conveyor belt

send

the labeled products to the collecting plate. |