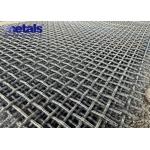

Customizable Woven Mesh Screen With Manganese Steel And Black Iron

Material

Crimped woven wire mesh offers great dimensional strength and

stability, great resistance to abrasion, uniform openings and

excellent anti-corrosion. It is usually used as quarry screen in

mine, quarry and other industrial fields as sieving, grading and

separating screening materials.

1. Angle: 30 degrees, 45 degrees,60 degrees

2. Crimped Wire Mesh Shape: v-shaped, u-shaped

3. Hook Type: C or U hook for 30°-180°

4. Weaving Type: Double crimped, intermediate crimped, flat top

crimped, lock crimped.

5. Mesh Type: Square, rectangular slot, long slot.

6. Surface Treatment: Anti rust oil painted.

7. Edge Preparation: Plain, bent, reinforced shroud, welded shroud,

bolt shroud.

Crimped Woven Wire Mesh Screen Specifications :

| NO. | Wire diameter (mm) | Aperture/ Hole size (mm) | Weight (kg/sqm) | | 1 | 12 | 75 | - | | 2 | 10 | 38 | - | | 3 | 9 | 32 | 25 | | 4 | 8 | 22 | - | | 5 | 7 | 25 | 19.5 | | 6 | 6 | 10 | - | | 7 | 4 | 10 | 14.5 | | 8 | 2.5 | 6 | 9.3 | | 9 | 2.2 | 4 | 10 |

Mesh Type of Crimped Quarry Screen Mesh:- Rectangular Slotted Mesh is economical to manufacture, and has a

greater open area for increased air flow where binding or clogging

occurs. The variable slot lengths mean it is often used to reduce

flake content of material to acceptable levels.

- Extra Long Slotted Mesh is manufactured with double or triple cross

wires. It is stronger and more cost effective in comparison to

Piano Wire or Self-Cleaning Screens. It provides a high open area

and higher throughput than normal slotted mesh, decreasing the risk

of clogging or binding.

- Square Mesh is the most cost efficient of the Woven Mesh range with

an expanded lifespan. The formation of the wire allows for

screening and production of regular shaped material. Square Mesh

decreases the risk of clogging.

- SELF CLEANING SCREENS are recommended where the prevention of

clogging and anti-pegging are required, or in very difficult areas.

Crimped and straight wires are connected by cross wires at regular

intervals. The wires vibrate independently of each other.

Weaving Type Of Crimped Quarry Screen Mesh:- Plain/Double: The plain weave is the most commonly used and

simplest to weave. It is a standard type of weave for wire cloth

resulting in square openings with wire sizes the same in both

directions. Each warp wire passes alternately over and under fill

wires at right angles, both directions.

- Twill Square: Each warp and shute is woven alternately over two and

under two warp wires. This gives the appearance of parallel

diagonal lines, allowing it to be used with heavier wires with a

particular mesh count (that is possible with the plain weave wire

cloth). This ability allows the applications of this wire cloth to

be used for greater loads and finer filtration.

- Twill Dutch: A filter cloth that offers higher strength than

regular Dutch weaves. It packs even more wires in a given area.

Each shute wire typically passes over two warp wires and under two,

producing square openings. Generally, this weave has finer mesh

counts and lower flow than regular Dutch weaves and can be made to

filter particles as fine as 2 microns in diameter.

|