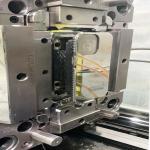

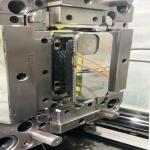

Protection phone case mould with high quality precise injection

mould

The production of injection molding molds for phone case protective

covers poses unique challenges and stringent requirements that must

be met to ensure the highest quality output. These molds are not

just tools; they are precision instruments that reflect the

combined expertise of mold design, assembly, machining

capabilities, equipment, team efficiency, and project management.

Firstly, the mold must produce cases with absolutely no burrs, even

the slightest ones. Burrs are unwanted protrusions that can occur

during the molding process and can significantly affect the

aesthetics and functionality of the final product. Eliminating

burrs is crucial as even minor ones cannot be tolerated and cannot

be removed through post-processing. This requirement necessitates

the use of high-precision machining techniques and mold design that

ensures smooth and continuous surfaces.

Secondly, the mold must exhibit minimal steps and parting lines.

These features are inevitable in the molding process but must be

kept to the bare minimum. The standard for this is that the steps

and parting lines should be visible but not palpable. This ensures

a seamless and visually appealing finish on the phone case. To

achieve this, the mold designer must carefully consider the

geometry of the part, the location of the parting lines, and the

choice of materials used in the mold.

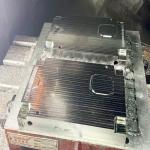

Thirdly, the mold must be designed for ease of production. This

involves factors such as the mold's structure, the complexity of

the cavity, and the efficiency of the cooling system. A

well-designed mold will reduce cycle times, improve production

rates, and minimize the risk of defects. It is also essential that

the mold is robust and durable, capable of withstanding the high

temperatures and pressures encountered during the injection molding

process.

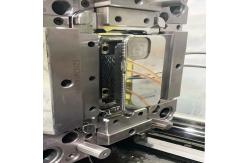

Lastly, delivery time is crucial. In today's fast-paced business

environment, being able to complete a project in the shortest

possible time is a competitive advantage. We pride ourselves on our

ability to deliver molds within three weeks, from design to

completion. This timeframe is a testament to our efficient team,

advanced machining equipment, and robust project management

capabilities.

Meeting all these requirements is a testament to our expertise in

mold design, assembly experience, machining capabilities,

processing equipment, team efficiency, and project management

abilities. We understand that each phone case protective cover mold

is unique and requires a tailored approach. By leveraging our

knowledge and skills, we are able to deliver molds that meet the

highest standards of quality and efficiency.