Structural type

Building block type barrel:

Each barrel can be interchanged, with extremely high processing

accuracy and strictly consistent installation dimensions. It can be

flexibly combined to meet different process requirements and is

currently the most popular barrel structure.

image

Mechanical extruder modular barrel

Split barrel: The barrel body can be opened like a shell, divided

into upper and lower leaves, which is easy to clean and maintain,

and is often used in scientific research experiments.

Closed barrel: There are no openings on the top, bottom, left or

right, suitable for processes that require a closed environment,

which can prevent material leakage and the entry of external

impurities.

image

Closed barrel of mechanical extruder

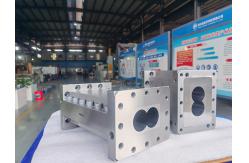

Open barrel: Usually used for feeding and venting, there is an

opening on the top of the barrel, which is convenient for the input

of materials and the discharge of gases during processing.

image

Mechanical extruder open barrel

Closed side feed barrel: There is no opening on the top of the

barrel, and the side opening is connected to the side feeder. It is

suitable for some special processes that require feeding from the

side.

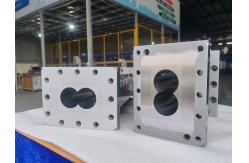

Top opening + side opening barrel: It is used for venting, and the

side opening is connected to the side feeder. This structure is

generally used in compact process layouts and can achieve both

feeding and venting functions simultaneously.

image

The mechanical extruder is equipped with a top opening and a side

opening barrel. The liquid feeding cylinder: There is a small

threaded hole on the upper part of the cylinder body, which is used

to connect the liquid injection gun or the liquid injection needle

valve, facilitating the injection of liquid materials into the

cylinder.