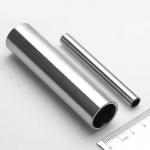

Nimonic 80A Seamless Pipe UNS N07080 Seamless Tube made by Hot Extrusion Press

|

|

Nimonic 80A Seamless Pipe UNS N07080 Seamless Tube made by Hot Extrusion Press

Nimonic 80A Seamless Pipe – High-Performance Nickel-Chromium Alloy Solution Nimonic 80A seamless pipes are precision-engineered from a precipitation-hardenable nickel-chromium superalloy, designed for extreme temperature and corrosive environments. These pipes combine exceptional creep resistance with superior mechanical strength, making them ideal for aerospace, power generation, and chemical processing applications.

Nickel (≥70%) + Chromium (19-22%) + Titanium (1.8-2.7%) + Aluminum (1.0-1.8%) Trace elements (Cobalt, Carbon, Zirconium) for enhanced stability ✔ Temperature Performance: Continuous service: 540-870°C (1000-1600°F) Retains 90% tensile strength at 750°C vs. standard stainless steels ✔ Mechanical Advantages: Tensile strength: ≥1,000 MPa (room temp) Oxidation resistance up to 1,100°C in air Excellent fatigue resistance under thermal cycling Manufacturing Excellence: Produced via extrusion/pilger mill process for uniform grain structure Ultrasonic tested (UT) and eddy current inspected Available in OD: 6mm-250mm | Wall thickness: 1mm-25mm Applications:

More grades: |

|

UNS N07718 Alloy 718 Seamless Pipe Hard-deformable Nickel-base Alloy Hot-extruded Seamless Tube |

|

Nimonic 901 UNS N09901 Seamless Pipe Alloy 901 Nickel Alloy Pipes |

|

Nimonic 80A Seamless Pipe UNS N07080 Seamless Tube made by Hot Extrusion Press |

|

Petroleum-Aerospace Alloy Inconel 718 Seamless Pipe, High-performance Nickel Alloy Seamless Pipe |

|

Thermal Processing Alloy 625 Seamless Pipes Nickel Alloy Pipe UNS N06625 with Customizable Surface |

|

Annealing Inconel 625 Welded Pipe Gas Turbine Components High-temperature Applying |