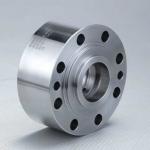

Hastelloy C-4 Valve Balls Hollow Trunnion Ball Without Stem

Valve trunnion ball usually refers to a key component in ball

valves. A ball valve is a valve that uses a sphere as an opening

and closing member. One hemisphere of the sphere is fixed on the

valve stem, while the other hemisphere can rotate to control the

flow of fluid. In ball valve design, the trunnion ball refers to

the part of the ball that is usually mounted on the trunnion of the

valve, allowing the ball to rotate when the valve opens and closes. The main functions and uses of valve trunnion balls include:- Flow Control: By rotating the trunnion ball, the flow of fluid through the valve

can be controlled. When the ball is aligned with the valve channel,

fluid can pass through smoothly; when the ball is rotated

perpendicular to the channel, fluid is blocked from flowing.

- Opening and closing operation: The trunnion ball moves with the rotation of the valve stem to

open and close the valve.

- High pressure resistance: The trunnion ball is designed to withstand high pressure

differences to ensure the sealing performance of the valve in high

pressure environments.

- Wear and Corrosion Resistance: Trunnion balls are usually made of wear and corrosion resistant

materials such as stainless steel, nickel alloys or other special

alloys to ensure that they maintain their functionality and

performance over long periods of use and under various operating

conditions.

- Reduce leakage: The design and material selection of the trunnion ball help reduce

leakage when the valve is closed and improve the sealing

performance of the valve.

The valve trunnion ball is an important component of the ball

valve, which directly affects the use effect and life of the valve.

In the chemical, oil, gas, pharmaceutical and other industrial

fields, especially where high pressure resistance, wear resistance

and corrosion resistance are required, valve trunnion balls play a

key role.

| Grade | UNS | density | DIN | | | Hastelloy C-4 | N06455 | 8.64g/cm³ | W.Nr.2.4610 | | | | | Chemical Composition(%) | Ni | Cr | Mo | Fe | Co | Ti | C | | Remainder | 14.0-18.0 | 14.0-17.0 | 3.0max | 2.0max | 0.7max | 0.015max | | Mn | Si | S | P | | | | | 1.0max | 0.08max | 0.03max | 0.04max | | | | Physical

Properties | Tensile Strength

( Mpa min) | Yield Strength

( Mpa min) | Reduction of Area ,min (%) | Elongation

min(%) | Hardness

(HRC) | | | 690 MPa min | 276 MPa min | …. | 40% min | … | | | |

DINGSCOHunan Dinghan New Material Technology Co., Ltd. (DINGSCO) specialized in Nickel Based Corrosion Resistant and High

Temperature alloys products which used in the world’s most technically demanding industries and applications.We are

dedicated to providing our customers with best quality products,

fastest possible deliveries, most competitive prices of Nickel

Based Corrosion Resistant and High Temperature alloys in bars, rods, forged flanges, valve parts (Ball, Stem, Seat Ring, etc), forged shapes (shafts, discs, blocks, hubs, rings, cylinders and other custom shapes) according to ASTM, ASME, API, AMS, NACE and other industry standards.

PROFESSIONAL NICKEL ALLOY MANUFACTURER - Monel, Incoloy, Inconel, Hastelloy

- VIM, ESR, Forging, Heat treatment, Machining

- Round Bar, Ball, Stem, Ring, Flange, etc

- ISO9001, API-6A, API-20B, PED, NORSOK

CORE VALUE - QUALITY ASSURANCE

- SCIENCE AND TECHNOLOGY INNOVATION STRATEGY

- COOPERATION

CUSTOMIZED PRODUCTS:

APPLICATION:

|