Huaheng Cold Cutting Process For Pipe Beveling

|

|

Previously, CNC lathes, gas cutting, or manual grinding were

utilized for beveling diverse materials. However, CNC equipment is

notably heavy and demands a considerable space in a fixed area.

Furthermore, it is difficult to convey or clamp large pipes. Also,

when a lathe is used, the pipe is rotated while cutting, which is

impractical for long pipes.

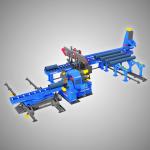

A high-quality and highly efficient integrated cutting and beveling process for small and medium-diameter thin-walled (≤25.4mm) pipes. This process is equivalent in efficiency to 10 sets of band saws and lathes combined. It takes only 2 to 3 minutes for cutting and beveling (two bevels) a 159 × 20 carbon steel pipe. One worker can replace ten workers. The savings in space occupation, labor cost, and electricity cost will recover the investment.

|

| Product Tags: Cold Cutting Process For Pipe Beveling Pipe Beveling machine |

|

Huaheng Cold Cutting Process For Pipe Beveling |

|

Container Design Pipe Edge Preparation Machine Work Station High Efficiency |

|

Container Design Pipe Cut Bevel Preparation Work Station |

|

Integrated Cutting And Beveling Machine Pipe Preparation Line |

|

Precise Cold Cutting Beveling Production Line For 8-24" Middle And Thick Wall Pipes |

|

Adjustable 3-Axis CNC Edge Beveling Machine For 5-90mm Wall Thickness |