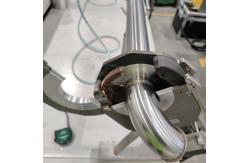

Good Quality All Position TIG Tube Welding Machine with Control Box

|

|

Automated all-position TIG welding addresses challenges in traditional manual welding, such as labor shortages and inconsistent quality. Advanced systems integrate robotics, real-time parameter adjustment, and remote monitoring, revolutionizing pipeline construction. Key Parameters

Advantages1, Labor Savings: Automated systems require minimal training (2–3 days for operators) and reduce workforce dependency. 2, Enhanced Productivity: Hot-wire TIG achieves deposition rates comparable to GMAW, cutting welding time by 50%. 3, Consistency: Pre-set parameters eliminate human errors (e.g., fatigue, skill variation), ensuring uniform bead appearance and mechanical properties Application Scenarios1, Urban Gas Pipelines: Portable automated TIG systems excel in confined spaces and complex layouts, common in municipal projects. 2, Shipbuilding and Offshore Platforms: Welding stainless steel or duplex pipes in harsh environments where manual welding is impractical. 3, Nuclear Facilities: High-integrity welds for reactor coolant pipelines, leveraging TIG’s low-spatter characteristics. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Control Box TIG Tube Welding Machine All Position TIG Tube Welding Machine Good Quality TIG Tube Welding Machine | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Good Quality All Position TIG Tube Welding Machine with Control Box |

|

High Precision All Position Tube to Tube TIG Welding Machine |

|

Magnetic Easy Installation Orbital Pipe Welding Machine High Reliability |

|

Four wheel Drive Semi Auto Orbital Pipe Welder Featuring DC24V 18RPM Swing Motor Pipeline Welding Machine |

|

6mm Thickness All Position Orbital Tube Welding With Magnetic Trolley |

|

Automation Accurate Control TIG Orbital Welding System With Magnetic Trolley |