Tunnel Kiln Electric Thermal Push-Plate Kiln Atmosphere Push Plate

Kiln

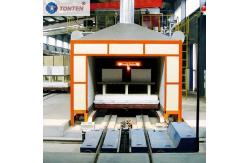

Introduction of Tunnel Kiln

Tunnel kiln is the main type of kiln in sintering brick factory.

Compared with wheel kiln which developed earlier, tunnel kiln has

high output, high degree of automation and low production cost. Its

structure is a brick masonry structure, lined with refractory

bricks, the top is paved with refractory cotton. Suitable for the

sintering of shale, coal gangue, clay, river mud, tailings and

other raw materials. The tunnel kiln designed by our company has

high yield, low consumption and excellent quality.

1. Tunnel kiln is a continuous production kiln with large output,

stable product quality and lower energy consumption than

intermittent kiln.

2. Tunnel kiln is divided into self-priming type and rotary flame

type according to the combustion mode; According to the different

temperature of the kiln is divided into high temperature and medium

temperature two categories.

3. Tunnel kiln has various structural forms. The kiln roof can be

flat suspended ceiling or arch structure, the lining material is

light or heavy firebrick, and the appearance can be steel frame

structure or red brick masonry. According to customer requirements,

there are also alloy furnace wire or carbon rod electric heating

tunnel kiln.

Summary of Advantages of Tunnel Kiln

Energy-saving and environmental protection assembly rotary tunnel

kiln set automation, digitalization, humanization, system into one,

less investment, high output, less labor, energy saving and

emission reduction, is today's domestic brick kiln model. It is

mainly composed of automatic walking kiln, ring track, ring power

supply system, ring billet transport system, automatic coal

blending, water distribution, strip cutting, billet cutting,

roasting system and other ancillary facilities. The kiln has the

following advantages:

1, less investment, the total investment than the same section of

the tunnel kiln saving more than 50%.

2, energy saving effect is good, the use of special high

temperature resistant insulation materials, and make full use of

heat energy, reduce heat loss.

3, the use of mechanization, digital, intelligent operation, less

labor, low labor cost, good working environment. Intelligent

roasting system is adopted, kiln partition temperature is uniform,

the brick quality is good, and the fired brick has no over-fire

brick or under-fire brick.

4, the furnace steel structure is compact, the internal insulation

material light weight, reasonable structure, scientific design,

less maintenance, low maintenance costs.

5, the construction period is short, from the exact entry of

construction to production, only less than three months.

Parameter Table of Tunnel Kiln

| Model parameter | rated

power

(thousand)

Watt) | Rated temperature

Degree (℃) | Working electricity

voltage | Temperature control group

Number (group) | Furnace size (mm)

Length x width x height |

| JKR-GMYS-65-17 | 65 | 1700 | 380 | 4 | 9000x180x200 |

| JKR-GMYS-85-17 | 85 | 1700 | 380 | 5 | 10000x200x220 |

| JKR-GMYS-100-17 | 120 | 1700 | 380 | 6 | 11000x220x220 |

| JKR-GMYS-120-17 | 120 | 1700 | 380 | 6 | 10000x220x250 |

| JKR-GMYS-150-17 | 150 | 1700 | 380 | 7 | 12000x250x250 |

| JKR-GMYS-180-17 | 180 | 1700 | 380 | 9 | 12500x250x280 |