Product Description ONE-STOP SOLUTIONS FOR WIRES&CABLES - HENAN UME CABLE CO., LTD

Over 30 years of Wires and Cables manufacture experience and Export to over 50 countries.

1. Applications

Copper Clad Steel wire is formed through the electroplating

method (taking steel wire as the core and depositing the copper

layer evenly on the surface of the steel core) and cladding method

(Cladding planished copper stripe concentrically on the outer

surface of the steel core), the copper-clad steel wire has the

combined advantages of both copper wire and steel wire, namely the

conductivity of copper wire and the strength of steel wire.

Moreover, it has 3 to 4 times the strength of pure copper wire and

3 to 5 times the conductivity of steel wire.

It is being widely used as a new generation of communication lines

and power transmission cables. Meanwhile, it is the lead wire

for electronics, carrying wire for the railroad, and wire for power

transmission, it is also used in bind wire, jewelry chain, piano

string cover, and pipe insulation wire.

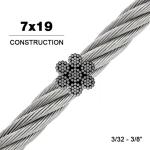

2. Construction

Copperweld strand is concentrically stranded cable of one or more

layers with left-hand lay in the outer layer unless otherwise

specified.

3. Standards

CCA Wiremeets or exceeds the following standards: ASTM B227, BS 4087, ASTM B 452, ASTM B 869. Place of Origin | China | Brand Name | UME | Type | Bare | Application | Overhead, power transmission | Conductor Material | Copper Clad Aluminum | Insulation Material | None | Specification | 16mm²-300mm² |

Product Parameters Physical Properties| | HARD DRAWN | SOFT | | Tensile | 110 ksi | 45 ksi | | Elongation | 1% | 10% | | Electrical Conductivity | 39% IACS* @ 68°F | 39% IACS* @ 68°F | | Electrical Resistivity | 26.45 cir mil ohm/ft @ 68°F | 26.45 cir mil ohm/ft @ 68°F | | Melting Point | --- | --- | | Density | 0.294 lbs/in³ | 0.294 lbs/in³ | | Thermal Coefficient of Resistance | 0.00210 Per °F | 0.00210 Per °F |

19-Strand Concentric Constructions| BARE CCS (40%) - HARD TEMPER | | AWG | CONST | DIAMETER (inch) | RESIST

(Ω/mft) | WEIGHT

(lb/mft) | BREAK STRG

(lb) | | MIN | MAX | MAX | MAX | MIN | | 18 | 19/30 | 0.0495 | 0.0505 | 14.5 | 5.47 | 160.9 | | 20 | 19/32 | 0.0395 | 0.0405 | 22.7 | 3.51 | 102.4 | | 22 | 19/34 | 0.0310 | 0.0320 | 37.0 | 2.20 | 63.1 | | 24 | 19/36 | 0.0245 | 0.0255 | 58.8 | 1.39 | 39.4 | | 26 | 19/38 | 0.0195 | 0.0205 | 92.9 | 0.899 | 25.0 | | 28 | 19/40 | 0.0150 | 0.0160 | 157.1 | 0.548 | 14.8 |

| BARE CCS (40%) - SOFT TEMPER | | AWG | CONST | DIAMETER (inch) | RESIST

(Ω/mft) | WEIGHT

(lb/mft) | BREAK STRG

(lb) | | MIN | MAX | MAX | MAX | MIN | | 18 | 19/30 | 0.0495 | 0.0505 | 14.5 | 5.47 | 65.8 | | 20 | 19/32 | 0.0395 | 0.0405 | 22.7 | 3.51 | 41.9 | | 22 | 19/34 | 0.0310 | 0.0320 | 37.0 | 2.20 | 25.8 | | 24 | 19/36 | 0.0245 | 0.0255 | 58.8 | 1.39 | 16.1 | | 26 | 19/38 | 0.0195 | 0.0205 | 92.9 | 0.899 | 10.2 | | 28 | 19/40 | 0.0150 | 0.0160 | 157.1 | 0.548 | 6.04 |

7-Strand Constructions| BARE CCS (40%) - HARD TEMPER | | AWG | CONST | DIAMETER (inch) | RESIST

(Ω/mft) | WEIGHT

(lb/mft) | BREAK STRG

(lb) | | MIN | MAX | MAX | MAX | MIN | | 22 | 7/30 | 0.0297 | 0.0303 | 39.1 | 2.01 | 59.2 | | 24 | 7/32 | 0.0237 | 0.0243 | 61.1 | 1.28 | 37.7 | | 26 | 7/34 | 0.0186 | 0.0192 | 99.3 | 0.803 | 23.2 | | 28 | 7/36 | 0.0147 | 0.0153 | 159.0 | 0.510 | 14.5 | | 30 | 7/38 | 0.0117 | 0.0123 | 250.1 | 0.328 | 9.20 | | 32 | 7/40 | 0.0090 | 0.0096 | 424.1 | 0.201 | 5.44 |

| BARE CCS (40%) - SOFT TEMPER | | AWG | CONST | DIAMETER (inch) | RESIST

(Ω/mft) | WEIGHT

(lb/mft) | BREAK STRG

(lb) | | MIN | MAX | MAX | MAX | MIN | | 22 | 7/30 | 0.0297 | 0.0303 | 39.1 | 2.01 | 24.2 | | 24 | 7/32 | 0.0237 | 0.0243 | 61.1 | 1.28 | 15.4 | | 26 | 7/34 | 0.0186 | 0.0192 | 99.3 | 0.803 | 9.50 | | 28 | 7/36 | 0.0147 | 0.0153 | 159.0 | 0.510 | 5.94 | | 30 | 7/38 | 0.0117 | 0.0123 | 250.1 | 0.328 | 3.76 | | 32 | 7/40 | 0.0090 | 0.0096 | 424.1 | 0.201 | 2.23 |

| | | | | | Grade 40 HS | Grade 30 HS | Grade 30 EHS | Grade 40 | Grade 30 | Grade 30 | Grade 40 | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Testing HENAN UME CABLE CO., LTD has a strict quality control policy in

every step from the order to After-sales service! Production: - Raw material inspection and test

- Production process test

- Unqualified product control

- Regular test and examination

- Finished product inspection

Certifications

UME CABLE has completed several third-party product certifications

to ensure our customers that all of the wire and cable purchased

and installed in your projects, will fully and consistently meet

all criteria of the required production and performance standards,

also you are guaranteed we (as the manufacturer) and the products

supplied are both valid and continuously monitored by those

globally recognized quality verification system listed as below:

ISO9001, ISO14001, ISO45001, CE, SGS, TUV. Packaging & Shipping Customer Visit Company Profile UME CABLE is one of the leading companies in the production and distribution

of cables and wires in China. As a manufacturer, we have supplied

quality products to more than 50 countries. Our mission is to offer

our customers the best quality cable and wire products at the most

competitive price, to extend and zoom the business success of our

partners, to make power reach where it is needed, to optimize the

running utility grids, and ultimately, to power the world. Our

version is to be the most customer-centric cable and wire company

with our solid technology, enthusiastic services, and robust

products. UME Cable was founded in 1994, located in Zhengzhou Gongyi Huiguo Town, and

occupies a total area of more than 200,000 square meters, with a

building area of 20,000 square meters. The real capital assets are

more than USD 6 million, with a total of 230 staff members, 35 of

which are professional and technical experts. The land of our

factory and employees numbers might not be the top scale of

industry, but our highly automatic facilities and elite employees

are the best in the industry will guarantee you a high yield rate

achieved by strict cost and quality control, this is why we could

quote better quality with the most competitive price within the

market.

FAQ Q1: Are you a manufacturer?

Yes, we are the manufacturer.

Q2: What are your main products?

Our products range as follows:

1. Electrical wire/PVC Building Wires.

2. PVC/XLPE insulated Power Cables up to 110kv.

3. Overhead Aerial Bundle Cable/ABC Cables.

4. Bare Conductors, like AAC, AAAC, ACSR, ACAR, ASCR/AW, and so on.

5. Steel wire/strand-like EHS, GSW and ACS(Aluminum Clad Steel),

CCS(Copper Clad Steel).

6. Rubber Cables, Mining Cables, Welding Cable, and Control Cables.

7. Concentric Cables with Copper/Aluminum/Aluminum Alloy 8000s'

Conductor.

Q3: Do you provide samples? Is it free or extra?

Yes, we could offer the samples for free.

Q4: Is the quality of your products guaranteed?

We have passed ISO9001, ISO14001, ISO45001, and all our

products have CE certificates.

Q5: Which markets do you involve mainly in?

Our products have been exported mainly to Africa, the Middle East,

Southeast Asia, South America, Central America, North

America, Europe, Australia, etc.

Q6: What is your payment term?

T/T or L/C.

Q7: What about the delivery time?

Generally, it is 3-7days if the goods are in stock. Or it is

7-30days if the goods are not in stock, it is according to

quantity.

|