Indron® ceramic bearings for pump and marine, developed by Techemer

Corporation, are engineered to meet the rigorous demands of

hydro-turbine pumps and marine environments. These water-lubricated

ceramic bearings offer exceptional wear and corrosion resistance,

making them ideal for applications where traditional steel bearings

may fail.

Ceramic Bearings Features and Advantages

INDRON ceramic bearing technology is leading the industry, and its

advantages of wear resistance and corrosion resistance are more and

more popular in the mining and chemical industries.

Superior Corrosion Resistance: Ceramic materials such as silicon nitride (Si3N4) and zirconium

oxide (ZrO2) exhibit excellent resistance to corrosion,

particularly in marine environments where exposure to saltwater is

common. This ensures prolonged bearing life and reliable

performance

High-Temperature Stability: Ceramic bearings maintain their integrity under high-temperature

conditions, preventing cold welding and wear failures associated

with high-speed, heavy-load operations. They can operate without

pre-lubrication, simplifying maintenance and enhancing reliability.

Reduced Friction and Wear: The inherent properties of ceramic materials result in lower

friction coefficients compared to steel, leading to reduced rolling

resistance, decreased energy consumption, and extended service

life.

Lightweight Design: Ceramic bearings are significantly lighter than their steel

counterparts, reducing the overall weight of machinery and

contributing to improved efficiency and performance.

Electrical Insulation: The non-conductive nature of ceramic materials prevents

electrical currents from passing through the bearings, eliminating

the risk of electrical erosion and extending bearing lifespan.

Water Lubricated Bearing Parameter Comparison

What bearing materials are more suitable as the materials used for

water pump guide bearings, Babbitt alloy, rubber, ceramics or new

polymer materials? It is advisable to take account of the

lubrication requirements, use environment and maintenance cycle of

the equipment.

COMMON GUIDE BEARING MATERIALS

| Bearing type | INDRON bearing | AR bearing | Ceramic bearing | Rubber bearing | Babbitt alloy bearing |

| Characteristics | The performance is close thordon, which can use more equipment

assembly methods. In addition to traditional installations by

freezing and pressurizing. It can also be installed by coating

reactive thermal polymerization Dx and cold sticking. | Good wear resistance and impact resistance. The bearing hardness is

high; the shaft sleeve is easy to wear; the temperature difference

changes greatly; there will be the risk of shelling; the price is

high. | Wear-resistant, heat-resistant, corrosion-resistant, lubricated by

pump circulating water, capable of dry grinding for a short time,

high requirement on accuracy in processing and assembly, fragile

and the most expensive. | It has a long history and mature manufacturing process, featured by

wear resistance, anti-seismic, impact resistance, convenient

assembly/disassembly and low price (only 20% of ceramic bearings

price) | Wear resistance and impact resistance require a set of more

complicated sealing and lubricating devices and mechanisms. |

| Lubricating requirements | Clean water can be used for lubrication or 150s dry start according

to the material grades. | Dry start more than 180S without clean water lubrication. | It can be lubricated by pumping medium without special clean water

lubrication. | Clean industrial water | Grease lubrication requires a grease supply lubrication system. |

| Working temperature | ≤70ºC | ≥273ºC | The bearing itself can withstand the temperature of 1,400ºC | ≤50ºC | ≤65ºC

Short time up to 80ºC |

| Application site | For pumping stations short of clean water or pumping stations

requiring short-term dry friction, hRBR grade is suitable for water

quality with moderate sediment content. | Pumping stations without clean water or pumping stations requiring

dry friction of more than 180S. | Pumping stations without clean water or pumping stations requiring

short-term dry friction. | Extensive application in any pumping stations with clean water

sources. | The liquid of the pump itself cannot be used for bearing

lubrication in the pumping station. |

| Bearing type | INDRON bearing | AR bearing | Ceramic bearing | Rubber bearing | Babbitt alloy bearing |

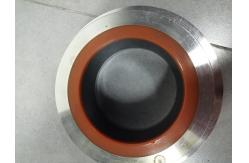

Products Show

Ceramic Bearings Applications

Indron® Ceramic Bearings are particularly suited for:

Hydro-Turbine Pumps: Their ability to operate efficiently in water-lubricated

environments makes them ideal for hydro-turbine applications.

Marine Equipment: The superior corrosion resistance of ceramic bearings ensures

durability and reliability in marine environments, where exposure

to saltwater and harsh conditions is prevalent.

Water-Lubricated Systems: The self-lubricating properties of ceramic materials make these

bearings suitable for systems where traditional lubrication is

challenging or undesirable.

Who Is Techemer Factory?

Our company will take integrity, quality first, customer first and

first-class service as its tenet.

| 01. Focus On Water Lubricated Bearings And Shaft Seals Since 2008 | 02. Offer Customized Bushes, Bearings And Seals Production |

| 03. Stabe Quality With Reasonable Price | 04. Fast Delivery With Online Service After Sale |

Our Strengths

Our senior material scientists and mechanical engineering

specialists have reached the international advanced level in

material design, material innovations, material manufacturing and

material applications. As a company focusing on the needs of

customers and possessing years of experience and professional

skills, we are assisting customers in solving their technical

problems and providing extraordinary material technology solutions.

Welcome to Contact Us!