WHY ARE SAPPHIRE WINDOWS SUCH HIGH PERFORMERS?

Sapphire windows and flat stock are incredibly hard, strong and

wear resistant:

A sapphire window can be exposed to extreme abradants such as sand

and particulates with minimal effect on the clarity of the window.

This makes sapphire windows the ideal material for a variety of

applications such as: Aerospace windows, downhole and drilling

vision systems, inspection windows, watch crystals and gun sights.

Sapphire windows can take pressure like no other clear material,

making sapphire windows the go-to transparent material for

high-pressure vessels, deep sea windows and sight glasses. Combined

with the exceptional thermal and chemical performance of sapphire,

a sapphire window is the ideal transparency for pressurized

in-process, deep sea and equipment sensors.

Sapphire flats and wear parts are used in applications in which

wear is a problem. Systems like canning machines, slide plates,

V-blocks, flat bearings and pushers utilize sapphire flats and

blocks to extend the lifetime of the equipment and reduce downtime.

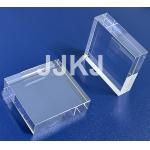

Sapphire Optical window Specifications:

| Product name | Sapphire Optical window |

| Material | Optical sapphire |

| Length | 1-500mm |

| Length Tolerance | ±0.03mm |

| Thickness | 0.1-100m |

| Thickness Tolerance | ±0.03mm |

| Parallelism | ≤3 ARC Min |

| Surface quality | DSP 60/40 |

| Chamfer | 0.1-0.3mm*45 Degree |

| Clear Aperture | 90% |

| Coating | According to customer needs |

Sapphire Components:

Sapphire's range of superior qualities make it ideal for optical

and non-optical components.

From the forward-facing optics of

imaging systems to the thermal insulators in plasma systems,

Sapphire's performance at extreme physical conditions often make it

the preferred choice for the following:

Lightguides

Sapphire offers higher working temperatures in applications such as

temperature thermometry and IPL systems, with a broad transmission.

Lenses

High optical quality Sapphire is used for lenses in systems that

require durability and ruggedness where standard materials suffer

from grit, impact and temperature damage. Sapphire lenses also

offer high performance in laser devices, offering high thermal

conductivity.

The broad transmission of Sapphire, across visible and NIR

spectrums, make it ideal for FLIR imaging systems in hazardous

environments, or where the reduced thickness of Sapphire lenses

lead to reduced system footprint.

Tubes

Sapphire tubes, made using the Stepanov growth method, replace

glass and quartz tubes in high temperature and pressure systems

such as plasma applications and insulators.

Pins and Rods

As well as the optical proporties offered by Sapphire rods for

fibre optcal and light-guide applications, the physical strength

and inert nature of Sapphire make it ideal for engineering and

structural uses