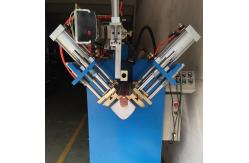

Fully Automatic CNC Welding Machine For Metal Sinks

|

Detailed Product Description

Fully automatic CNC welding machine for metal sinks

Specifications:

Advantages:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Fully Automatic CNC Welding Machine Metal Sinks CNC Welding Machine Metal Sinks Welding Machine | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Related Products

|

Special Numerical Control Welding Machine for Planar Splicing of Stainless Steel |

|

Special Automated Welding Machine for Planar Splicing in Sink Manufacturing |

|

Special Automated Welding Machine for Planar Splicing of Industrial Sheet Metal |

|

Special Numerical Control Welding Machine for Planar Splicing of Metal Sheet Metal |

|

Special Numerical Control Welding Machine for Sheet Metal Splicing |

|

The Application of Numerical Control Welding Machine for Metal Sheet Metal |

Email to this supplier