Product Description:

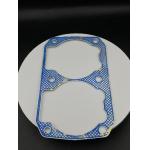

Mold making is a process used to create molds from various

materials, such as metal, , and silicone. The size and shape of the

mold can be customized according to the customer's needs, and

colors can also be customized. Depending on the complexity and size

of the mold, the lead time may be short or long. The surface of the

mold can also be customized to be either smooth or rough. The mold

assembly process is an important part of the mold creation process,

as it ensures that the mold will be properly formed and be able to

accurately create the desired product.

Features:

- Product Name: Mold making

- Mold Life: Short/Long

- Mold Type: Injection/ Compression/ Extrusion/ Blow

- Mold Base: Standard/Customized

- Ejection System: Standard/Customized

- Runner System: Hot/Cold

- Mold Construction: Design, Production, Machining, and Assembly

- Mold Production: CNC Milling, Wire EDM, and Surface Grinding

- Molding Technology: Precision injection molding, Compression

molding, Extrusion molding, and Blow molding

Technical Parameters:

| Mold Construction | Molding Process |

|---|

| Surface: Smooth/Rough | Size: Customized |

| Color: Customized | Ejection System: Standard/Customized |

| Cavity Number: Single/Multi | Runner System: Hot/Cold |

| Mold Type: Injection/ Compression/ Extrusion/ Blow | Material: Metal//Silicone |

| Mold Base: Standard/Customized | Mold Life: Short/Long |

| Mold Creation | Mold Design |

|---|

| Material: Metal//Silicone | Mold Tooling: Standard/Customized |

Applications:

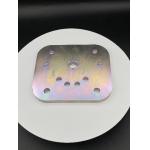

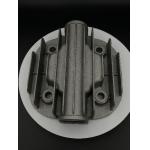

Mold making is an important process in the production of cylinder

head. It involves mold assembly, mold designing, and molding

process. The molding process includes quality control, mold life,

ejection system, surface, and color. Mold life can be short or

long, depending on the customer's needs. Ejection system can be

standard or customized. Moreover, the surface can be smooth or

rough. The color can also be customized according to the customer’s

demand. The mold type can be injection, compression, extrusion, or

blow molding. All these aspects are taken into consideration when

it comes to making the perfect cylinder head.

Customization:

Customize your cylinder head with our mold fabrication services.

Our mold creation and mold manufacturing services provide

custom-made molds with a place of origin in Xiamen, China. We offer

both standard and customized mold bases, shapes and cavities, and

provide molds of injection, compression, extrusion and blow molding

types made from metal, and silicone materials.

Support and Services:

Mold making technical support and services include:

- Design and manufacturing of injection, silicone, and rubber molds

- Design and fabrication of die-casting molds for aluminum, zinc, and

other metals

- Design, manufacture, and assembly of specialized molding tools

- Troubleshooting molding and assembly problems

- Mold repairs and maintenance

- Mold flow analysis and optimization

- Mold sampling and validation

- Mold design services

- Prototyping services

Packing and Shipping:

Packaging and Shipping of Mold making:

Mold making products are carefully packaged in an appropriate box

and shipped in the safest and most secure way.

The box is designed to protect the product from damage during the

shipping process. The box is also labeled with a tracking number so

that the customer can easily track the product.

The product is usually shipped via a reputable courier service,

such as FedEx, UPS, DHL, or USPS. The shipping time and cost vary

depending on the destination.

FAQ:

- Q: What is the brand name of the mold making?

- A: The brand name of the mold making is cylinder head.

- Q: Where is the mold making produced?

- A: The mold making is produced in Xiamen, China.

- Q: What materials are used in the mold making?

- A: The mold making is made of high-quality steel.

- Q: How long does it take for the mold making to be completed?

- A: It usually takes around 2 to 3 weeks to complete the mold

making.

- Q: What is the life expectancy of the mold making?

- A: The life expectancy of the mold making depends on the usage and

maintenance, but it generally lasts up to 5 years.