Fast Install Directly Supply Steel Structure Building Warehouse Heavy Duty Prefabricated Warehouse

|

|

Fast Install Directly Supply Prefab Warehouse Steel Structure Building Heavy Duty Prefabricated Warehouse China Factory Product Description:

Steel Structure Workshop The primary difference between the two steel building types is the primary framing system. The primary framing system is the core framing of a building. Welded frame buildings are made with frames from steel flat bars and flat sheet pieces that are welded together. The columns and rafters are typically tapered, being narrow at the foundation and peak and wider at the rafter/column connection. Steel Structure Workshop A cold-formed building’s main frame is typically both bolted and screwed together using pre-drilled plates. Cold-formed steel buildings can require some cutting/coping and drilling of braces on site. A welded frame steel building’s main frame is bolted together with plates already welded in place by our certified welders in our weld shop. Welded frame buildings can require some drilling on site. Steel Structure Workshop The quality of the materials used in pre-engineered steel buildings plays a huge role in how long they’ll last. When you’re checking out options for pre-engineered steel buildings, make sure to look at the quality of the steel, insulation, and roofing materials to ensure they can handle the unique environmental conditions in the region. 1. Primary FramingPrimary Frames are the main load-carrying structural steel components. They may be Clear-span Rigid Frames, Continuous Beam Frames, or Post & Beam Frames. Primary frames are designed in accordance with the steel construction manual published by American Institute of Steel Construction (AISC). Manufacturing dimensional tolerances are in accordance with the requirements of ‘Metal Building Manufactures Association’ (MBMA) of USA, “Low Rise Building Systems Manual”. Besides AISC and MBMA, we also design buildings with IS-875, 1984 and IS-875, 2007. Built-up sections are fabricated from hot rolled steel plates confirming to ASTM A 572M grade or equivalent with minimum yield strength of 345N/mm2 (50ksi). The most common primary framing systems are illustrated here. All structures shown are symmetrical about the ridge line. Framing systems unsymmetrical about the ridge line and Multi span Framing Systems with unequal width modules are possible too. Practically any frame geometry can be erected. 2. Secondary Framing (Bracing, Z and C section purlin)Purlin, tie bar and bracing are secondary structural members used to support the wall and roof cladding. Secondary members as purlin, tie bar, column bracing and horizontal bracing connect the main frame and help in resisting part of the longitudinal loads that are applied on the building such as wind and earthquake loads. Steel purlin is available in high grade steel conforming to GB/T 2518-2008, Q235B/Q345B Grade or equivalent, available in 1.8 mm. 2.0 mm, 2.2 mm, 2.5 mm and 3.0 mm thickness. The purlin come with a galvanized sheet. Column bracing is a connecting member set between two adjacent columns to ensure the overall stability of the building structure, improve lateral stiffness and transfer longitudinal horizontal force. Column bracing will be round steel or angle steel according to the building need. 3. Steel Decking FloorThe pressed steel plates supporting the floor concrete are called profiled plates, also called floor bearing board.The steel decking board are widely used in multi-storey buildings such as power plant, exhibition hall, steel structure workshop, cement warehouse, steel structure office, airport terminal, railway station, stadium, concert hall, grand theater, large supermarket, logistics center, Olympic venues and sports venues and other steel structure buildings.It can adapt to the main steel structure rapid construction requirements, can provide a firm platform in a short time, and can take flow repetitive construction operation, laid a number of floors decking board, and pouring concrete slab. Features:

Steel structure Design Technical Parameters:

Please kindly inform us of the information below if you are interested in our products.

We can provide :1.Customization Service We have a professinal design team about 20 people, with 10 years design experience. We can meet your individual needs. And multi-type steel components, roof and wall panels, doors and windows for choosing. 2. Strict Quality Inspection With good quality steel material, we have AWS-D1.1/D1.5 welding quality system and professional CWI welding inspector to ensure high quality of the product. 3. Shortest Delivery Time We have 2 modern factories and 3 production lines with a total area of 150000 square meters to produce. We guarantee a warehouse of 5000 square meters and delivery within 30 days. 4. Production Visualization We can provide you with picture,video information of all production links, from raw materials to steel processing, the whole process of visual production. You can even video call us to watch workshop production. 5. Packing and Delivery Container and pallet packing will protect the surface paint or zinc of the steel structures. In order to facilitate your installation, we will mark each component in sequence according to the drawings. 6. Installation Guide Installation instruction and video will be provide, we can also send our engineers to your site as installation guide, they will teach your people how to build project. Installation scene:

THREE ways to help you on the installation: 1. We can offer you the manual include the photos and drawings, or some videos for help you on the installation. And you will organize the local people to install it. 93% of our clients finished their houses in this way. Applications:

Please kindly inform us of the information below if you are interested in our products. Project Cases:

Our capacity and certification:

Support and Services:

Our team of experts is available to provide technical support and services for the Prefab Steel Warehouse product. We offer:

Our goal is to provide our customers with reliable, durable, and cost-effective solutions for their storage needs. Contact us for more information on our technical support and services. Why Choose Us to offer steel structure building:1.We have a group of professional engineers, most of whom has more than 20 years experiences in architecture field. our company has got a various of experiences in design, manufacture, installation and so on. The work staff have excellent skills. Some of them had helped customers to install the warehouse around the world. 2. We will offer one stop service. construction drawing,calculation sheet will be offered to help you get construction permit. Foundation design could be free made if you need. We could make 3D drawings to show the view. What's more, Installation drawings will be offered and Steel structure column,beams will be marked number on it to help you install. 3. We will send you extra bolts,purlins,panels incase any damage when install. 4. Efficiency is our pursuit. Every inquiry ,emails will be replied immediately. Every questions will be paid high attention. 5. We also have possessed more than 40 sets of large precise and domestically advanced processing equipments, including large gantry planing machines, automatic submerged arc welding machines, assembling machines, slitters, shot blasting machines and soon. 6.We will offer details packing list for every container when load so it will be easier to unload. 7. "Moral personality decides product quality." is our guarantee to the products. "Customers come first." is our everlasting pursuit. Believe your choose, we'll give you a satisfied answer. Company profile:

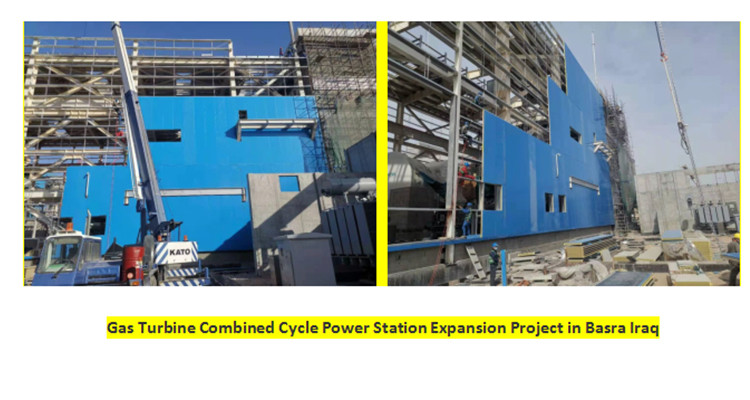

Baodu International Advanced Construction Material Co., Ltd was established in January 2010 with the office in Beijing and factory in Hebei, China. Baodu is a designer, manufacturer, supplier and exporter of industrial noise comprehensive treatment, steel structure, sandwich panel and prefab house. Baodu has an annual output of 6 million square meters of acoustic sandwich panels, 100000 tons of steel structures and 1 million square meters of floor decking sheet. The products are sold in more than 30 countries and regions around the world. Baodu has a professional design team with more than 10 years’ experience, including 5 senior engineers, 20 engineers, and 35 technicians. Baodu has several energy saving and environment protection intellectual property rights, construction and environment protection design qualification, CE certification and Russian GOST certification etc. Baodu participated in the military parade village project for the 60th anniversary of China and project of Beijing Daxing International Airport. Under the guidance of China's "one belt, one road" strategy, Baodu has also undertaken overseas projects such as the project of Thar,Pakistan coal fired power plant, Hasyan Dubai power plant and so on. Finally, welcome your coming to Baodu for a visit and cooperation!

Packing and Shipping:

Product Packaging:

Shipping:

FAQ:1. How to buy your idea products?

Q: What is the payment method and supply ability for this product? A: The payment terms for this product include L/C, D/A, D/P, T/T, Western Union, and MoneyGram. The supply ability for this product is 10000 Square Meter/Square Meters per month and the price is reasonable. |

| Product Tags: Fast Install Prefabricated Warehouse Heavy Duty Prefabricated Warehouse Directly Supply Prefabricated Warehouse |

|

Easy Installation Industrial Prefabricated Warehouse Building For Garage |

|

Structural Prefabricated Metal Warehouse Construction Building Eco Friendly |

|

Fast Install Assembly Prefabricated Steel Warehouse Custom Design |

|

Fast Assembly Modern Prefab Steel Warehouse Buildings Eco Friendly |

|

Fast Assembly Large Garage Prefab Warehouse Building |

|

Customizable Versatile Prefab Metal Warehouse Commercial Building |