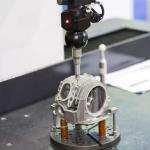

CNC 3D CMM Measuring Machine , Portable Coordinate Measuring Systems

|

WM-3D High-accuracy Portable 3d Cnc Optical Coordinate Measuring Machine Price Cmm Three Coordinate Measuring MachineProduct Description1.Include CMM main machine, machine support, imported precise air filter, imported measuring system.

2.The not-pieced granite table make the machine have good load capacity, spacious room for objects being measured, easy to load and unload.

3.The slide way for the three axis use high quality granite, enabling them have the same temperature characteristics. Therefore, the following advantages can be achieved: good temperature stability, resist deformation by time, fine rigidity, minimal geometrical deformation.

4.The application of non-linear spring reduces minor error of the slide way towards the measuring precision; meanwhile it also guarantees machine’s higher adaptability to the environmental temperature.

5.The girder adopts the triangle guide way structure( triangle is with the longest circumference in the same area section), which can guarantee the maximum air bearing span on the condition of the least inertia and increase the guide way’s anti- torsion precision greatly.

6.Z-axis’s torsion plays a critical role in the precision of a CMM. Its reliable anti- torsion structure design also can achieve a high precision in the case of using probe extension bar.

7.The separating vibration design of the driving system still can minimize the measuring precision effects because of machine’s vibration, although the machine is moving with high speed.

8.The 3 axis adopts high performance hold-in range, which not only can assume great speed to increase the measuring efficiency, but also reduce the driving inertia to enhance the acceleration.

9.Z-axis adopts the regulable pnaeumatically actuated balance device, which can adjust the counterbalance with facility although equipped with different probe systems, so that it can reach the high point.

10.Length measuring system adopts imported metal zonal Scale and Read head, both of which can assure high precision accuracy and stability.

11.The imported high-precision air filter on the machine can assure the high purity of the compressed air, so that the air bearing and the slider way could be protected. In the meantime, the automatic drainage device makes operators economical with time and effort, avoiding the possible harm to the machine caused by man-made negligence.

12.Safety protection design ,works effectively while machine fault.

13.Ergonomic mechanical design,Easy operate and maintenance. Support and ServicesOur CNC visual measurement machine products are equipped with comprehensive technical support and service packages to ensure optimal performance and minimal downtime.In terms of warranty, the CNC visual measuring machine offers a 12-month warranty, providing users with greater peace of mind. This ensures that any issues or malfunctions can be resolved promptly and effectively, guaranteeing that the machine always operates at its best condition. Here are our services:

Packaging and TransportationPackaging:

Transportation:

Frequently Asked QuestionsQ: Where is this size screening machine produced? Q: What brand is this machine? Q: What does this machine mainly detect? Q: Does this machine have any certifications? Q: What are the packaging details of this machine? Q: What is the minimum order quantity for this machine? Q:What is the payment condition for this machine? Q:What is the delivery time for this machine? Q: What is the price of this machine? |

|

CNC 3D CMM Measuring Machine , Portable Coordinate Measuring Systems |

|

3D Coordinate CMM Measuring Machine Equipment 2.2MPE Um Accuracy |

|

Portable CMM Testing Machine , Optical 2.4um CMM Measurement System |

|

High Precision CMM Measuring Machine Equipment Bridge Type Three Coordinate |

|

Digital CMM Coordinate Measuring Machine High Precision Multifunctional |

|

Electronic CMM Measuring Machine System 3D Automatic Bridge Type |