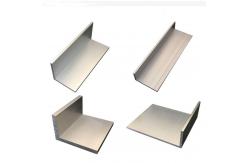

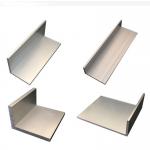

High Quality Extruded Aluminum Angles Equal Angle Standard Shapes

|

|

High Quality Extruded Aluminum Angles Equal Angle Standard Shapes

Delivering Timely Excellence: Premium Extruded Aluminum Angles

Specification

Parts of Ready-to-use Molds:

Product Introduction

Product superiority

1.As part of our commitment to excellence, we offer pre-treatment

methods such as sand-blasting. This process prepares the raw

extruded profiles by creating matte surfaces and effectively

removing surface dirt and oil stains. Our advantages

1.Benefit from our extensive experience of more than 15 years in

manufacturing aluminum profiles.

Workshop

Inspection equipment

FAQ

Are you a manufacturer or a trading company?

Where is your factory located?

How do you provide quotations?

What is the lead time for manufacturing new molds?

Do you offer samples? If yes, is there a cost associated?

What is your delivery time? |

||||||||||||||||||||||||||||||||||||||||

| Product Tags: High Quality Extruded Aluminum Angles Equal Angle Extruded Aluminum Angles standard shapes Extruded Aluminum Angles | ||||||||||||||||||||||||||||||||||||||||

|

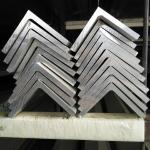

Industrial Anodizing Aluminium Bar Structural Aluminum Industrial Profile H Shape |

|

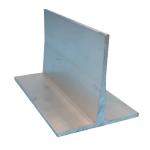

Customized Aluminium Alloy T Profiles Shape Aluminium Alloy Tile Trim For Decorate Wall Corner |

|

T Shape Aluminium Building Blocks Profile T Shape Bar Manufacturer Extruded T Track |

|

6061 Premium Customized Extruded Unequal Aluminum Angle With Kinds Of Molds |

|

High Quality Extruded Aluminum Angles Equal Angle Standard Shapes |

|

Industrial Anodizing Aluminium Angle Bar Structural Aluminum Beams OEM ODM |