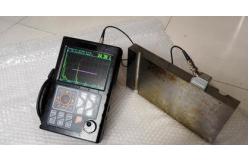

Product Description:

Gate alarm function is complete, strong anti-interference

ability;

Reserved encoder, can be configured 16 in/16 out and other I/O

interfaces;

System configuration is simple and flexible, in order to achieve

the requirements of more channels;

High reliability, easy maintenance;

Self-developed control interface, user-friendly, operable;

Software modularity, can be configured according to the needs of

the

Small size, big wisdom, easy to carry.

Translated with DeepL.com (free version)

Application:

A Special advantages

1. Full digital, true colour display, according to the environment

to choose the background colour, brightness value can be set

freely, leading the tide of domestic applications.

2. Digital shuttle knob, one-button operation

3. Spectrum analysis, high-speed FFT operation, the actual probe

frequency

4. High-performance security lithium-ion batteries, modular

plug-in, a machine, two power, two charging

B Launch Pulse

1. Pulse Strength: Graduated selection, set up 200V, 300V, 400V,

applicable to a wide range of probes

2. Pulse Width: 100-300ns continuously adjustable to match the

optimal sensitivity of the probe at different frequencies.

3,Impedance: 51-51V, 300V and 400V. The best sensitivity when

probing

3. impedance matching: 51Ω, 150Ω, 200Ω, 400Ω, to meet the

sensitivity and resolution of the different requirements of the

work

4. working mode: single crystal probing, double crystal

probing

C Scanning range

Zero interface incidence ~ 14,000mm (longitudinal wave of the

steel), proportional adjustment, continuous adjustment of the two

modes.

D Amplification and reception

1. hardware real-time sampling: 150MHz, waveforms with high

fidelity

2. detection mode: full detection, positive and negative detection,

RF wave display

3. gate signal: single gate, double gate, full screen retrieval,

peak readings within the gate.

4. value-added / full-automatic gain: set 0.1dB, 2dB, 6dB step

value, set the amplitude of the wave height value of the

full-automatic gain mode

E Alarm

Gate, sound and light alarms within the curve and shut down

F Data Storage

1. 50 groups of fast selection of the detection parameters of the

channel, pre-tuned to the various types of probes and the

combination of instrumentation parameters, free to set up the

detection standards of various industries, easy to store, call,

retesting, printing and communication transmission

2. Memory of 1000 echo signals and data of flaw detection, to

achieve the computer management of storage, reading out and

browsing, single printing, continuous printing and communication

transmission.

3. Parameter attachment: full Chinese setup flaw detection

parameters, input real-time data, random storage, call, print,

report communication

G flaw detection function

1. Wave memory: real-time retrieval of the highest wave defects,

calibration defects maximum value

2. φ value calculation: straight probe forging flaw detection to

find the defects of the highest wave automatically converted

to

3. Crack altimetry: to find the defects of the highest wave,

real-time diffraction method of altimetry

4. Dynamic recording: detection of the real-time dynamic record

Waveforms, storage, playback

5. Defect location: real-time level value L, depth value H, sound

range value S

6. Defect quantification: real-time SL quantitative value

7. Defect characterization: through the envelope waveform,

artificial empirical judgement

8. Surface modification: curved surface workpiece flaw detection,

modified curvature conversion

9. Distance compensation: real-time compensation for long-distance

flaw detection of thick workpieces to avoid leakage of detection of

small defects

10. The form of weld profiles: real-time flaw detection describes

the sound range process, to achieve defect location 11, crack

height measurement: find the highest wave of defect, real-time

diffraction method height measurement Acoustic process to achieve

defect location

11. B-type scanning: real-time scanning, describing defects in the

cross-section

H Real-time clock records

real-time flaw detection date, time tracking records, and

storage

I Control Interface

High-speed USB, RS232 two kinds of interfaces to provide the

transmission of printing

J Screen Protection

Standby can be turned off the screen to make the instrument to save

power, reduce the number of switching times, to prolong service

life

Technical Parameters:

| Name | Portable Ultrasonic Flaw Detector HY-87F |

|---|

| Detection mode | Full detection, positive and negative detection, RF wave

display |

| Operating frequency | 0.5MHz ~ 20MHz (bandwidth optional: 0.5-4MHz, 2-8MHz, 10MHz,

2MHz-20MHz) |

| The frequency band noise level | <15% |

| Attenuator accuracy | < ±1dB/12dB |

| Gain adjustment | 110dB (0.1dB, 2dB, 6dB step, fully automatic adjustment) |

| Sound speed range | (100 ~ 20000) m/s |

| Dynamic range | ≥ 30dB |

| Vertical linearity error | ≤ 3% |

| Horizontal linearity error | ≤ 0.1% |

| Resolving power | <40dB (5N14) |

| Digital suppression | (0 ~ 80)%, does not affect the linear and gain |

| Power supply, voltage | DC (DC) 7.2V ± 10%; AC (AC) 220V ± 10V |

Support and Services:

1. From the date of completion of installation and commissioning of

the equipment, as the beginning of the quality assurance period of

the equipment. The supplier will warranty the equipment for one

year and implement lifelong maintenance service for the equipment.

In the equipment warranty period of the relevant costs borne by the

supplier, in the equipment warranty period outside of the relevant

costs of the supply side only charge material costs.

2. The equipment into normal operation after the supply side will

still be ready for the demand side to provide all the technical

advice

3. In the use of equipment in the process of the demand side can

not be resolved by the demand side of the technical problems, the

supply side in the receipt of the demand side's request, should be

answered and put forward solutions

FAQ:

Q1: What is the brand name of this product?

A1: The brand name of this product is Desisen.

Q2: What is the model number of this product?

A2: The model number of this product is HY-87F.

Q3: Where is this product made?

A3: This product is made in China.

Q4: Does this product have any certification?

A4: Yes, this product has ISO9001 certification.

Q5: What's the minimum order quantity?

A5: The minimum order quantity is 1.