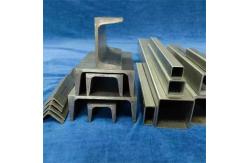

Cold Rolling Titanium Channel Profiles In Grade Gr1 With Bright Finish

|

|

Cold Rolling Titanium Channel in Grade Gr1 with Bright Finish Product Description:Titanium alloys have been widely used in aviation industry and aerospace technology due to their high specific strength, heat resistance and corrosion resistance. The hot extrusion method has become an effective choice for the production of titanium ally profiles as it enables materials to possess the best three-way compressive stress state, thus yielding higher quality products. The hot extrusion process also offers a greater degree of flexibility in replacing varieties and improving product economics.

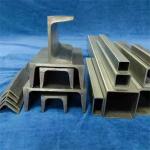

Nonetheless, the importance of enhancing the straightening process of U profile should not be overlooked, as it directly affects the accuracy of product dimension and its performance. Therefore, to improve the straightening performance of U profile, this study investigated the effects of straightening heating temperature and cooling rate on straightening deformation, microstructure and properties of U profile.

The results indicated that when the cooling rate is set, increasing the straightening heating temperature results in a better straightening deformation effect. Conversely, when the straightening heating temperature is kept constant, a greater cooling rate leads to a smaller resilience after high temperature straightening deformation, as well as a better straightening deformation effect of U profile. The experiments also revealed that the straightening heating temperature should not be higher than 720℃ in order to maintain the integrity of structure and properties.

Titanium Channel Profiles

Technical Parameters:

Applications:Titanium metal and alloy have excellent mechanical, physical and chemical properties, such as good heat resistance, low temperature toughness and fracture toughness. Therefore, it has been used widely in the aerospace field, such as the manufacture of aircraft engines, rocket and missile components. In addition, titanium alloys are also used in the aeronautical and astronautic industry to create fuel and oxidizer container, high-pressure vessel, as well as automatic rifles, mortar mounts and recoilless gun tubes. Packing and Shipping:Packaging and Shipping The Titanium Channel product is packaged with a professional exterior to ensure safe delivery. The packaging is designed to protect the product from any potential damage during shipping. The product is shipped using a reputable and reliable shipping provider. All orders are shipped with tracking information and delivery confirmation. Customers will be provided with the necessary information to track their order. FAQ:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Cold Rolling Titanium Channel Gr1 Titanium Channel Bright Finish Titanium u section | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Gr1 Gr2 Gr5 Titanium Channel Cold Or Hot Rolling ASTM B348 / ASME B348 |

|

Machining Titanium Alloy U Channel Gr7 U Section Steel Channel |

|

Cold Rolling Titanium Channel Profiles In Grade Gr1 With Bright Finish |

|

Customizable Titanium Metal Channel U Shaped Channel Profiles TP550 TP450 |

|

Gr10 Grade Titanium Channel TP270 U Shaped Metal Channel |

|

U Shaped Titanium Channel Gr6 Gr7 Sheet Metal U Channel Profiles |