Antiwear Wave Soldering Fixture Cleaning Machine 550KG with Rotating Spray

|

|

Rotating spray fixture cleaning machine720 degree all-round spraying TW-CL4000

Characteristic: 1.The one button operation,equipment cleaning,rinsing,drying,cutting wind the whole process is finished automatically,without manual intervention;

2.The cleaning batch is large, which can save a lot of labor. The cleaning room is equipped with a visual window, and the cleaning room is equipped with lighting bulbs, making the cleaning process clear at a glance;

3.After cleaning, the surface of the workpiece is dry, with high cleanliness, adjustable spraying pressure, and 720 degree all-round spraying, ensuring no dead corners during cleaning;

4.The equipment has a real-time circulating filtration system for cleaning and rinsing liquids, and the filtration system is equipped with pressure monitoring function, greatly improving the efficiency of liquid utilization and prompting for filter element replacement;

5.The equipment has low energy consumption, low operating noise, no pollution, and a good environment;

6.All air pressures need electronic alarm monitoring meters. When the air pressure is not up to the standard, it will automatically stop and give an alarm;

Working principle: Manual insertion - pump pressurization - centralized 10um filtration - spray online cleaning - recovery - pump pressurization - online 0.45um three-level filtration - spray online rinsing - wind cutting drying - heating drying - manual removal

Technical Parameter:

FAQ:

|

||||||||||||||||||||||||||||||||||||||||||||

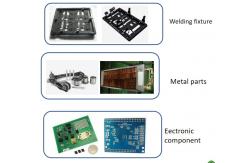

| Product Tags: Antiwear Wave Soldering Fixture Cleaning Machine Spray Wave Soldering Fixture Cleaning Machine 550KG Rotating Spray Fixture Cleaning Machine |

|

Stable Wave Soldering Fixture Cleaning Equipment Multiscene Antiwear |

|

Practical Wave Solder Fixture Cleaner , Industrial Wave Soldering Washing Equipment |

|

10m3/Min Wave Soldering Fixture Cleaning Equipment Durable Multipurpose |

|

Antiwear Wave Soldering Fixture Cleaning Machine 550KG with Rotating Spray |

|

AC380V Wave Soldering Fixture Cleaning Equipment 50HZ Practical |

|

32KW 80L Wave Soldering Fixture Cleaner , Wave Soldering Pallet Flux Cleaning Machine |