Customizable Cogging Test System for Motor Production Process

Improvement

Product Description:

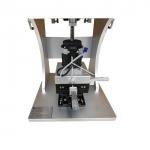

Precision Motive's Cogging Test System is a standalone system that

has been specifically designed to measure Detent Torque, Cogging

Torque, and Friction Torque.

The system boasts a precision geared motor and a JT Series Torque

Sensor which integrates a 5,000 pulse encoder. The system's JT101

to JT303 come equipped with built-in security clutches that ensure

the system won't overload or mishandle when not in use.

The system is operated by driving the Motor Under Test (MUT) with

the geared motor at a low speed that ranges from 1-10 rpm (although

other speeds are available as an option). During this time, the

system will acquire the MUT's cogging torque related to angle

position. Torque measurement with the system covers a range of up

to 2 N·m (depending on the selected torque sensor) with an accuracy

of ± 0.1 mN·m (for JT 101 – 10 mN·m and JT 303 – 3000 mN·m).

The system's executable software controls the system and displays

any acquired data. It is capable of providing accurate peak-to-peak

measurement of cogging torque and displays both X-Y and polar

graphs, as well as FFT analysis. It also allows for the storage of

measured data and provides a comparison of performance data by

overlaying up to 5 graphs. A cursor can be used to read accurate

values from measurement points. Measured parameters can also be

saved as a text file TXT.

Additionally, the software includes a zero offset adjustment

routine which checks the transducer signal over a complete turn

(with the test sample MUT not connected to the system). This

ensures that the system operates with maximum accuracy and function

control.

Technical Parameters:

Mechanical Characteristics

The following table lists the mechanical characteristics for

various models of a product:

| MODEL | Rated Torque (RT) | Accuracy |

|---|

| JT-500 | 5 mN.m | 1% of RT |

| JT-101 | 10 mN.m | 0.5% of RT |

| JT-501 | 50 mN.m | 0.2% of RT |

| JT-102 | 100 mN.m | 0.2% of RT |

| JT-302 | 300 mN.m | 0.2% of RT |

| JT-502 | 500 mN.m | 0.2% of RT |

| JT-103 | 1 N.m | 0.2% of RT |

| JT-303 | 3 N.m | 0.2% of RT |

Measurement Characteristics

The following characteristics relate to the measurement function of

the product:

- Speed range: 1 to 10 rpm (other speed ranges can be customized)

- Angle detection: 0.018° (5000 pulses/rotation)

- Test direction: clockwise & counterclockwise

Environmental Requirements

The product has certain environmental requirements:

- Working temperature range: +10℃ to +45℃

- Storage temperature range: 0℃ to +70℃

- The effect of temperature on zero position: 0.01% / ℃

- Protection level: IP 42

Electrical Characteristics

The following table lists the electrical characteristics of the

product:

| Power requirement | Communication port | The connecting cable includes |

|---|

| 220-240 VAC / 50 Hz (max. 1 A) | USB-B2.0 | A 2m USB cable |

Applications:

Whether you are in the automotive, aerospace, or manufacturing

industry, the JT Cogging Test System is perfect for assessing the

cogging vibration of your machines and equipment. With a weight of

only 10kg, this product is portable and easy to use, making it

ideal for both on-site and laboratory use.

The Precision Motive JT Cogging Test System boasts a

high-resolution of 0.0001 Nm, providing you with accurate and

precise measurements every time. Additionally, the software for

this product is Windows-based, allowing for easy data analysis and

reporting. This feature makes it easy for you to keep track of your

measurements and analyze them in real-time, ensuring that you can

make informed decisions quickly.

The JT Cogging Test System is designed to operate within a wide

temperature range, making it suitable for use in different

environments. With a storage temperature range of -20°C to 40°C,

you can be sure that your product is safe and secure, even in

extreme temperatures.

If you are looking for a reliable and accurate magnetic cogging

measurement system, look no further than the Precision Motive JT

Cogging Test System. With its advanced features and easy-to-use

interface, this product is perfect for a wide range of applications

and scenarios.

Customization:

Support and Services:

The Cogging Test System product technical support and services

include:

- Assistance with installation and setup

- Troubleshooting and diagnosis of issues

- Maintenance and repair services

- Calibration and testing services

- Software updates and upgrades

- Technical documentation and user manuals

- Training and education services for operators and technicians

Packing and Shipping:

Product Packaging:

The Cogging Test System will be securely packaged in a cardboard

box with foam inserts to prevent any damages during transit. All

necessary accessories and manuals will be included in the package.

Shipping:

Shipping will be done through our trusted courier partners. Once

the order is confirmed and payment is received, the product will be

dispatched within 2 business days. The estimated delivery time will

depend on the destination and the courier service chosen by the

customer.

FAQ:

Q: What is the brand name of this product?

A: The brand name of this product is Precision Motive.

Q: What is the model number of this product?

A: The model number of this product is JT.

Q: Where is this product made?

A: This product is made in China.

Q: What is the purpose of the Cogging Test System?

A: The Cogging Test System is designed to measure and analyze the

cogging torque of motors and generators.

Q: What industries can benefit from using the Cogging Test System?

A: Industries that design and manufacture motors and generators

such as automotive, aerospace, and power generation can benefit

from using the Cogging Test System.