GH2747 High Temperature Alloy Rod High Strength Structure Stability Oxidation Resistance GH747

|

|

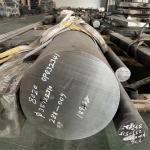

GH2747 high temperature alloy rod high strength structure stability oxidation resistance GH747. GH2747 is a Fe-Ni-Cr based precipitation hardening high temperature alloy with excellent high temperature strength, corrosion resistance and good mechanical properties. It is widely used in aerospace, nuclear power, petrochemical and metallurgical industries. GH2747 is a Fe-Ni-Cr based precipitation hardening deformation high temperature alloy, which is widely used in many fields for its excellent high temperature resistance, corrosion resistance, high strength and high toughness. This alloy is used in the solid solution state, and the long-term working temperature can reach 1100℃-1250℃, and the short-term use temperature can reach 130 Chemical composition Nickel (Ni): 44-46%, giving the alloy excellent high temperature

strength and corrosion resistance.

Physical properties Density: 8.26 g/cm³.

Performance characteristics Anti-oxidation and corrosion resistance: By increasing the chromium content and adding rare earth elements in appropriate amounts, the alloy's anti-oxidation properties at 1000℃-1300℃ are effectively improved. Welding performance: GH2747 has good weldability, high strength and good toughness of the welded joint, and can be welded using various processes. Processing performance: The alloy has good processing performance, is easy to form and weld, and can be hot forged, hot rolled, heat treated, etc.

Available forms Plate, bar, seamless tube, wire, forging We can also provide other parts according to customer requirements. Hot-rolled and forged bars delivered in rolled or forged state, diameter 5-200 mm. Seamless steel tubes delivered in cold-drawn or solid + pickled state, diameter 1-100 mm.

Application fields Aviation industry: used to manufacture high-temperature components such as combustion chambers and afterburners. Due to its excellent oxidation resistance and corrosion resistance, it can maintain a stable organizational structure in a high-temperature environment. Petrochemical industry: suitable for reactors, heat exchangers and other equipment that require long-term heat and corrosion resistance. Nuclear energy industry: used to manufacture high-temperature and radiation-resistant components to ensure the stability of materials in extreme environments. Metallurgical industry: used for heat-resistant furnaces, furnace linings and thermocouple protection sleeves to meet the needs of creep resistance and corrosion resistance in high-temperature environments. |

||||||

| Product Tags: High Temperature Alloy Rod Oxidation Resistance Alloy Rod High Strength Alloy Rod |

|

Inconel 601 Alloy Rod NS313 Alloy Round Steel Alloy 601 Seamless Pipe Size Customized |

|

GH2747 High Temperature Alloy Rod High Strength Structure Stability Oxidation Resistance GH747 |

|

High Strength Incoloy 800H Nickel Based Alloy Round Bar N08810 Black 10-100mm Anti-stress Corrosion Cracking |

|

Nickel Based Temperature Alloys Inconel625 Steel Bar Forged Round Bar Round Steel UNS NO6625 Bar Flaw Detection Qualified |

|

High Strength 2.4660 N08020 Corrosion Resistant Alloy 20 High Temperature Rod |

|

Inconel 625 Round Steel Forgings Black Rod Oxidation Resistant Alloy 625 Alloy Plate |