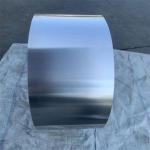

20# Alloy Is A Low-Carbon Steel With Good Machinability And

Weldability For Structural Use.

20# Alloy is a medium-carbon steel primarily used for structural

and mechanical applications where a good balance of strength,

toughness, and wear resistance is required. This steel grade is

known for its reliability in various industrial contexts due to its

favorable combination of mechanical properties and ease of

processing.

Chemical Composition:

20# Alloy contains the following key elements:

- Carbon (C): 0.17-0.23% – The carbon content provides a good balance of

strength and hardness while maintaining reasonable ductility and

machinability.

- Manganese (Mn): 0.35-0.65% – Manganese improves tensile strength and hardness, and

also contributes to the alloy's toughness and wear resistance.

- Silicon (Si): ≤0.35% – Silicon aids in deoxidization during steelmaking, which

helps to produce a cleaner steel with a smoother surface finish.

- Phosphorus (P): ≤0.035% – Low phosphorus content helps avoid brittleness and

ensures that the steel remains tough and ductile.

- Sulfur (S): ≤0.035% – Sulfur is kept low to minimize inclusions and ensure

better machinability and overall strength.

Mechanical Properties:

20# Alloy offers a range of mechanical properties suitable for

various applications:

- Tensile Strength: 370-530 MPa – Provides strong resistance to pulling forces, making

it suitable for structural and mechanical uses.

- Yield Strength: ≥245 MPa – The yield strength ensures that the material can

withstand significant stress without permanent deformation.

- Elongation: ≥25% – Indicates good ductility, allowing the steel to be

stretched or formed without breaking, which is important for

fabrication and shaping.

- Density: Approximately 7.85 g/cm³ – Typical for medium-carbon steels,

balancing strength with weight.

- Hardness: HB 150-200 – Provides good wear resistance while retaining

sufficient flexibility and machinability.

Applications:

20# Alloy's balanced properties make it suitable for a range of

structural and mechanical applications:

- Construction: Used for manufacturing structural components such as beams,

columns, and frames, where moderate strength and good weldability

are required.

- Mechanical Parts: Ideal for producing various mechanical parts and components,

including shafts, gears, and axles, where durability and resistance

to wear are needed.

- Automotive Industry: Employed in the production of automotive components that require a

combination of strength and formability, such as engine parts and

transmission components.

- Metal Fabrication: Suitable for general metal fabrication, including the production

of plates, rods, and tubes that need to be machined or formed.

Summary:

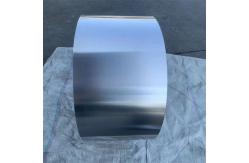

20# Alloy is a versatile medium-carbon steel known for its

well-rounded mechanical properties, including a good balance of

strength, ductility, and hardness. Its chemical composition and

performance characteristics make it suitable for a variety of

structural and mechanical applications, from construction and

automotive parts to general metal fabrication. With its reliable

performance and ease of processing, 20# Alloy is a preferred

material in industries requiring durable and adaptable steel

solutions.