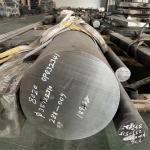

High Temperature Resistant Inconel 718 Alloy Round Bar N07718 Polished Rod

|

|

High Temperature Resistant Inconel 718 Nickel-Based Alloy Bar N07718 Polished Rod

Inconel 718 Alloy Introduction: Inconel 718 alloy is a precipitation-hardened nickel-chromium-iron alloy containing niobium and molybdenum. It has high strength at 700°C, good toughness and corrosion resistance in both high and low temperature environments. It can be supplied in solution treated or precipitation hardened state. Composition of inconel718 alloy: unit%

Inconel718/alloy718 is a Fe-Ni-Cr based precipitation hardening deformation high temperature alloy, with a long-term use temperature range of -253~650 degrees Celsius, a short-term use temperature of 800 degrees Celsius, and high strength, good toughness and oxidation and corrosion resistance in high and low temperature environments below 650 degrees Celsius. It also has good processing performance, welding performance and long-term organizational stability. Features: Metallographic structure: Corrosion resistance: Application Scope:

1. Steam turbine

If you have any questions that need to be answered, you can always contact us. We are happy to answer them for you. Wishing you a wonderful day |

||||||||||||||||||||||||||||||||||||||||

| Product Tags: Inconel 718 Alloy Inconel 718 Round Bar N07718 Polished Rod |

|

Inconel 601 Alloy Rod NS313 Alloy Round Steel Alloy 601 Seamless Pipe Size Customized |

|

GH2747 High Temperature Alloy Rod High Strength Structure Stability Oxidation Resistance GH747 |

|

High Strength Incoloy 800H Nickel Based Alloy Round Bar N08810 Black 10-100mm Anti-stress Corrosion Cracking |

|

Nickel Based Temperature Alloys Inconel625 Steel Bar Forged Round Bar Round Steel UNS NO6625 Bar Flaw Detection Qualified |

|

High Strength 2.4660 N08020 Corrosion Resistant Alloy 20 High Temperature Rod |

|

Inconel 625 Round Steel Forgings Black Rod Oxidation Resistant Alloy 625 Alloy Plate |