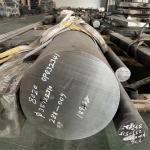

GH20 Alloy is a high-performance nickel-based superalloy renowned

for its exceptional properties in extreme environments. Engineered

for high-temperature applications, GH20 exhibits remarkable

strength, thermal stability, and resistance to oxidation and

corrosion. Its composition includes nickel, chromium, cobalt, and

other elements tailored to enhance mechanical properties and heat

resistance.

Key Features:

- Composition: Predominantly nickel with chromium, cobalt, molybdenum, and other

alloying elements that contribute to its robust performance.

- Temperature Resistance: Effective in environments up to 900°C (1650°F), maintaining its

structural integrity and mechanical properties.

- Mechanical Properties: Offers high tensile and yield strength, ensuring reliability and

durability in demanding applications.

- Corrosion and Oxidation Resistance: Designed to withstand harsh conditions, extending the lifespan of

components.

- Applications: Ideal for use in aerospace engines, gas turbines, and other

high-stress components where high-temperature performance is

critical.

- Heat Treatment: Can be heat-treated to achieve desired mechanical properties and

performance.

GH20 Alloy's advanced properties make it suitable for critical

aerospace and industrial applications, providing long-term

reliability and durability.

Here’s a detailed composition table for GH20 Alloy:

| Element | Composition (%) |

|---|

| Nickel (Ni) | Balance |

| Chromium (Cr) | 19.0 - 21.0 |

| Cobalt (Co) | 10.0 - 12.0 |

| Molybdenum (Mo) | 3.0 - 4.0 |

| Tungsten (W) | 2.0 - 3.0 |

| Titanium (Ti) | 2.0 - 2.5 |

| Aluminum (Al) | 1.0 - 1.5 |

| Carbon (C) | ≤ 0.08 |

| Silicon (Si) | ≤ 0.50 |

| Manganese (Mn) | ≤ 0.50 |

| Boron (B) | ≤ 0.01 |

These values are approximate and can vary slightly based on

specific production standards and requirements.