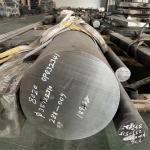

GH3044 Alloy

GH3044 is a high-performance nickel-based superalloy designed for

exceptional strength and oxidation resistance in high-temperature

environments. This alloy is predominantly used in the aerospace and

power generation industries due to its superior mechanical

properties and resistance to extreme conditions.

Key Features:

- Composition: Primarily composed of nickel, chromium, and iron, with additional

elements like molybdenum, tungsten, and titanium that enhance its

properties.

- Temperature Resistance: Capable of withstanding temperatures up to approximately 1370°C

(2500°F), making it ideal for applications in high-heat

environments.

- Strength: Exhibits high yield and tensile strength, providing reliable

performance under stress and load conditions.

- Oxidation Resistance: Excellent resistance to oxidation and sulfidation, ensuring

longevity and durability in harsh conditions.

- Applications: Commonly used in gas turbines, aerospace components, and other

high-temperature industrial applications where strength and

reliability are critical.

GH3044 alloy's unique combination of strength, temperature

resistance, and corrosion resistance makes it a preferred choice

for demanding engineering applications, contributing to enhanced

performance and extended service life of components.

Feel free to adjust this description based on specific needs or

additional features of the alloy you want to highlight.

Here’s a detailed composition table for GH3044 alloy:

| Element | Content Range |

|---|

| Nickel (Ni) | Balance |

| Chromium (Cr) | 20.0-22.0% |

| Iron (Fe) | 5.0-7.0% |

| Molybdenum (Mo) | 4.0-5.0% |

| Tungsten (W) | 0.5-1.5% |

| Cobalt (Co) | 1.0-2.0% |

| Aluminum (Al) | 0.8-1.2% |

| Titanium (Ti) | 1.0-2.0% |

| Boron (B) | 0.005-0.015% |

This table provides a clear overview of the alloy's chemical

composition, crucial for understanding its performance

characteristics.