Front Stencil Mixing Extruder/Pre-screen Extruder

Pre-screen Extruder is a key piece of equipment in the brick and tile production line,

primarily used for raw material pre-processing and primary forming.

Positioned before the vacuum extruder, it is referred to as a

"pre-screen" device. This equipment screens and preliminarily

compresses the raw material through a mesh plate, preparing it for

subsequent vacuum extrusion molding.

Raw Material Pre-processing: Performs preliminary extrusion and homogenization of mixed raw

materials to improve uniformity.

Impurity Filtration: Filters out large impurities and unbroken hard lumps through the

mesh plate.

Enhanced Vacuum Extrusion Efficiency: Pre-compresses the material, reducing the workload on the vacuum

extruder.

Improved Product Quality: Ensures more uniform material, minimizing defects in finished

bricks.

Downstream Equipment Protection: Prevents large hard objects from entering the vacuum extruder and

causing damage.

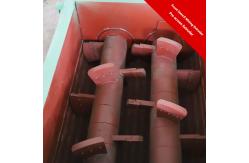

Structural Features

Mesh Plate System: The core component, made of high-strength wear-resistant steel,

with adjustable apertures based on product requirements.

Extrusion Screw: Utilizes a variable-diameter and variable-pitch design to

gradually increase extrusion pressure.

Drive System: Equipped with a high-power motor and gear reducer to provide

stable torque output.

Casing Design: Heavy-duty and robust construction, lined with wear-resistant

materials to extend service life.

Technical Features

High Processing Capacity: Capable of 30-100 tons/hour (depending on model specifications)

Adjustable Pressure: Extrusion pressure controlled by regulating mesh aperture and

screw rotation speed

Wear-Resistant Design: Critical components made with special alloys or wear-resistant

coatings

Automated Control: Can integrate with full-line automation systems for intelligent

adjustment

Request a Free Consultation

Ready to upgrade your brick production? Contact our experts for a customized solution!