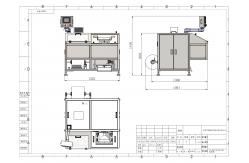

In Line counting visual Packing Machine For bathroom fittings sanitary

|

|

Features Overview of In Line counting visual Packing Machine For bathroom fittings

sanitary Sepecification Parameter

Princeple

Applicable Industry 1.Pharmaceutical Packaging:The pharmaceutical industry has strict regulations regarding product quantity. Visual counting machines meet these requirements by precisely counting pills and capsules, ensuring patient safety. 4. Hardware Distribution:For the vast range of hardware items, from nails to large - sized bolts, these machines can efficiently count and package them. This streamlines the hardware supply chain. 5. Plastic Product Assembly:Whether it's plastic pipes or plastic utensils, visual counting machines can handle different - shaped plastic products. They assist in maintaining production efficiency and inventory control. 6. Horticulture and Floriculture:Counting flower bulbs, seeds, and young plants becomes easy. It helps in the proper management of horticultural products from cultivation to market. 7. Warehouse Management:In busy warehouses, visual counting machines quickly count products during receiving, storage, and shipping. This enhances overall warehouse operational efficiency. Machine Detail CCD camera counting We use CCD camera to check quantity of the products to avoid errors

which by weighing machine. Japanese brand "TOSHIBA" camera. Counting in real time. High accuracy! Hign speed! CCD camera counting

Touch control screen Multiple channel for accurate counting

PE film economic packing material

Adavantages Visual counting packaging machine adavantages 1. Error - Elimination Benefit:Advanced image technology provides pinpoint - accurate product

counting, eliminating costly errors. 2. Productivity - Boost Benefit:Automated counting and packaging lead to a substantial increase in

productivity, generating more output in less time. 3. Flexibility - Gain Benefit:The ability to work with diverse products, materials, and packaging

styles gives businesses greater flexibility in production. 4. Quality - Assurance Benefit:Pre - set programs ensure consistent packaging quality, enhancing

brand reputation. 5. Cost - Reduction Benefit:Cutting down manual labor directly reduces labor costs and the

risks associated with human error. 6. Management - Ease Benefit:Recording vital data simplifies quality tracking and inventory

control, streamlining business operations. 7. Safety - Enhancement Benefit:Safety features prevent accidents, protecting both workers and

equipment, and reducing potential losses. Intelligence:With powerful learning functions,the machine can automatically

recognize the particle object,and can be easily accessed and used

after slight manual adjustments and save. Precision:Precision:With leading high precision in the field of industrial

product.The procision of silver contact products can even reach

over 99.95% High-speed:High speed for counting particles.The efficiency of counting small

particles of materials(such as shirt buttons,silver contacts,phone screws,ect.)can reach up to 30000pcs/min with accurate counting. Flexible:With one click cleaning and quick swithching of product

items,suitbale for multi variety and small batch production of

granular packaging forms in today's industrial production

environmen Optional Series |

||||||||||||||

| Product Tags: visual Packing Machine bathroom fittings Packing Machine sanitary Packing Machine |

|

Multifunctional easy operation Vision Counting Packing Machine for pipe fitting manufacturers |

|

Multifunctional counter and packer Vision Counting Packing Machine For stainless steel fitting |

|

High efficiency visual Packing Machine For stainless steel fittings |

|

In Line counting visual Packing Machine For bathroom fittings sanitary |

|

Strong Versatilities Multifunction Vision Counting Packing Machine For Plastic Pipe Fitting Packing |

|

Multi Function Vision Counting Packing Machine For Pipes Fitting Packing |