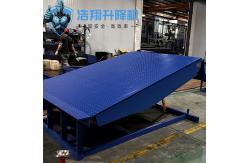

Blue Adjustable Height Hydraulic Truck Dock Leveler Product Description: The Hydraulic Dock Leveler is a heavy-duty, high-performance loading dock solution designed to

streamline warehouse operations. Featuring a robust steel construction and hydraulic-powered lifting (+400mm/-300mm stroke), it ensures smooth, precise alignment with

trucks for efficient loading/unloading. Customizable voltage (380V or other) and frequency (50Hz/60Hz) make it adaptable to global standards, while its 495mm anti-slip lip plate and 8T–20T load capacity guarantee safety under heavy use. With push-button controls, pit or surface mounting options, and 1-year warranty, this dock leveler combines durability, flexibility, and ease of

operation—ideal for logistics centers, warehouses, and industrial

facilities seeking reliable, long-term material handling

efficiency. Here’s a highly detailed technical breakdown of the Hydraulic Dock Leveler in English, covering specifications, installation, maintenance,

and customization options:

1. Core Structure & Working PrincipleKey ComponentsHydraulic System Cylinder: High-strength steel, pressure-resistant (≥20MPa), ensures smooth

lifting. Power Unit: Motor (2.2–4kW, customizable), with overload relief valve.

Lip Plate Dimensions: 495mm (length) × 0.5" (thickness), anti-slip steel with diamond

tread or coated surface. Hinge Mechanism: Spring/hydraulic auto-return for tight truck sealing.

Control Panel

Operation FlowDocking: Lip extends to bridge the gap between dock and truck. Leveling: Hydraulic adjustment (±10mm precision) to match truck bed height. Loading: Forklifts/pallets move safely with even weight distribution.

2. Technical Parameters (Deep Dive)| Parameter | Details |

|---|

| Load Capacity | 8T/12T/15T/20T (reinforced frame for heavy-duty). | | Lifting Stroke | +400mm (max rise)/-300mm (max lower), speed: ~100mm/s (adjustable). | | Power Supply | 380V 3-phase (standard), customizable (220V/460V/60Hz). | | Installation | Pit-mounted (pit depth ≥500mm) or surface-mounted (with ramp). | | Environment | Operating temp: -20°C to +50°C, humidity ≤90% (rust-proof

treatment). |

3. Installation & CommissioningPre-InstallationFoundation: Concrete ≥200mm thick (C30 grade), anchor bolts pre-positioned

(tolerance ≤5mm). Electricals: Dedicated circuit breaker (32A recommended), grounding resistance

≤4Ω.

Step-by-Step InstallationPit Prep: Verify dimensions (W1870×D500×H2280mm), clear debris. Positioning: Use forklift/crane to place leveler, check levelness (≤2mm/m

deviation). Final Fixing: Bolt down, connect hydraulic hoses/power (ensure correct phase

sequence).

Testing

4. Maintenance & TroubleshootingRoutine CareWeekly: Check hydraulic oil level (ISO VG46), lubricate chains (lithium

grease). Monthly: Clean guide rails, tighten bolts (torque ≥50N·m).

Common Issues| Symptom | Cause | Solution |

|---|

| Slow movement | Low oil/clogged filter | Refill/replace filter. | | Lip won’t retract | Broken spring/valve stuck | Replace/clean valve. | | Motor overheating | Voltage fluctuation/overuse | Check power, cool down. |

5. Customization & Selection GuideKey ConsiderationsLoad: Light (<8T) = mechanical; heavy (>15T) = reinforced

cylinder. Frequency: High-use (>200 cycles/day) → add oil cooler. Environment: Cold climates → low-temp hydraulic oil (-40°C).

Optional FeaturesSafety: LED warning lights, guardrails. Integration: Weighing system (±1% accuracy), PLC automation. Dimensions: Lip extendable to 600mm (wide trucks) or narrowed to 1500mm.

6. Advanced ApplicationsCold Storage: Stainless steel construction + anti-freeze oil. Smart Warehouses: PLC + WMS compatibility (RS485/Modbus). Hazardous Zones: Explosion-proof motor (ATEX certification).

7. Comparison with Alternatives| Type | Hydraulic | Mechanical | Air Cushion |

|---|

| Maintenance | Moderate (oil changes) | Low | High (cushion wear) | | Precision | ±5mm | ±15mm | ±20mm | | Max Load | 8T–30T | <6T | <2T |

|