FWM-100 Robotic Welding Machine 1000W-3000W for Industrial Automation

|

|

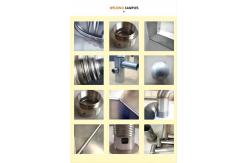

Safety flexible Robotic Welding equipment with Speed and Efficiency

1-Automation: Robot welding equipment automates the welding process, reducing the need for manual labor. It improves consistency and speed in high-volume production environments.

2-Precision and Consistency: Robots are equipped with advanced sensors and controllers that ensure high-precision welding. This results in consistent welds with minimal defects, which is crucial for industries like automotive, aerospace, and manufacturing.

3-Flexibility: Robot welding systems can be programmed to handle various welding processes, including MIG, TIG, and spot welding. They can also be reprogrammed to handle different parts and welding configurations, making them adaptable to a variety of applications.

4-Speed and Efficiency: Robotic welders operate faster than human workers, leading to higher throughput and reduced production times. They can work 24/7 without fatigue, making them ideal for high-volume manufacturing.

5-Safety: By automating dangerous welding tasks, robotic systems reduce the risk of injury to workers. The robots are often housed in protective cages or safety zones to prevent accidents.

|

|||||||||||||||||||||||||||||||||

| Product Tags: Flexible Robot Welding Machine Robot Welding Machine 1000w | |||||||||||||||||||||||||||||||||

|

FWM-100 Robotic Welding Machine 1000W-3000W for Industrial Automation |

|

High-Speed Robot Arc Welding Machine 1000W-3000W Industrial Grade |

|

FWM-100 Robot Welding Equipment with Push-Pull Feeder and 30kg Load |

|

FWM-100 Robotic Welding Machine with Air Water Cooling and Data Analytics |

|

High-Speed Robot Arc Welding Equipment with Low Maintenance |

|

FWM-100 Robot Welding Equipment 0.5-2m/min Speed DN50-DN1000 Range |