In the automotive domain, the safety and comfort of passengers

hinge on the reliability and durability of every component within

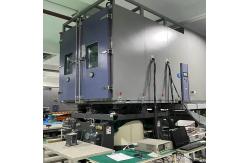

the vehicle. The HALT HASS & AGREE Vibration Test Chambers,

meticulously crafted for NES M0131 High Temp testing of passenger

parts, emerge as a cornerstone in the pursuit of automotive

excellence. This state-of-the-art vibration test chamber is dedicated to

subjecting passenger parts to the exacting NES M0131 High Temp

testing protocol. It caters to automotive manufacturers, Tier 1

suppliers, and research institutions. The primary objective is to

evaluate the performance and integrity of passenger parts such as

seat components, dashboard elements, door trims, and interior

fittings under the combined duress of high temperatures and

vibration. By replicating the most extreme and realistic conditions

that these parts may face during a vehicle's operational lifespan,

manufacturers can unearth potential design flaws, optimize

materials and manufacturing processes, and ultimately enhance the

overall quality and safety of the automotive passenger experience. - Robust and Thermally Stable Chamber Construction

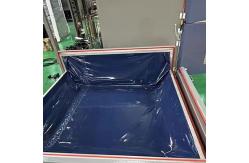

- The chamber is constructed with heavy-duty, heat-resistant

materials that can withstand the rigors of high-temperature and

vibration testing. The walls are fabricated from a combination of

high-strength steel and advanced thermal insulation layers,

ensuring minimal heat loss and a stable internal temperature

environment. The interior is designed to accommodate a diverse

range of passenger parts, with adjustable racks and fixtures that

guarantee proper positioning and uniform exposure to both heat and

vibration. The door is equipped with a precision sealing mechanism

and a heat-resistant viewing window, enabling operators to monitor

the testing process without compromising the integrity of the

chamber's internal conditions.

- Precision Temperature and Vibration Control Systems

- Temperature Control: Capable of achieving a wide temperature range

from ambient to +150°C with an accuracy of ±0.3°C. The system

employs state-of-the-art heating elements, along with a

sophisticated PID controller and multiple temperature sensors, to

maintain a precise and uniform temperature throughout the chamber.

This allows for the simulation of various high-temperature

scenarios that passenger parts may encounter, from the sweltering

heat of a parked vehicle in a sun-drenched parking lot to the

elevated temperatures near engine components.

- Vibration System: The chamber is outfitted with a high-performance

vibration platform that can generate a broad spectrum of vibration

frequencies and amplitudes. It can produce vibrations from 5 Hz to

2000 Hz with amplitudes up to 50 mm. The vibration system is

engineered to replicate the diverse vibration sources experienced

in a vehicle, including engine vibrations, road surface

irregularities, and the dynamic forces associated with vehicle

maneuvers. The vibration control system offers exceptional

precision, allowing for the programming of complex vibration

profiles and real-time adjustments to mimic different driving

conditions.

- Intuitive Control Panel and Data Acquisition Interface

- The control panel is designed with user-friendliness in mind,

providing operators with effortless access to all test parameters.

They can easily set and adjust temperature levels, vibration

frequencies, amplitudes, and test durations. The panel also

presents real-time information regarding the current temperature,

vibration status, and any alarms or warnings. The chamber is

integrated with a comprehensive data acquisition system that

records all pertinent test data. This encompasses temperature

histories, vibration waveforms, and any observable changes in the

physical or mechanical properties of the passenger parts. The data

can be stored in a built-in memory or exported to external storage

devices for in-depth analysis. The system is also capable of

generating detailed test reports in various formats.

- Safety Features and Alarms

- To ensure the safety of operators and the protection of the test

specimens and the chamber itself, a suite of safety features is

incorporated. These include over-temperature and over-vibration

protection systems, emergency stop buttons, and alarms for abnormal

temperature fluctuations, vibration malfunctions, or any other

equipment failures. The chamber is also equipped with proper

ventilation and exhaust systems to handle any potentially harmful

gases or vapors that may be emitted from the passenger parts during

high-temperature testing.

- Temperature Range and Accuracy

- The broad temperature range from ambient to +150°C with ±0.3°C

accuracy provides a comprehensive testing spectrum. This allows

manufacturers to assess the performance of passenger parts not only

under normal operating temperatures but also in extreme heat

scenarios. For example, components like plastic knobs or electronic

displays need to remain functional and aesthetically intact even

when exposed to temperatures well above typical ambient conditions.

The accurate temperature control ensures that the test conditions

are precisely maintained, providing reliable and repeatable

results.

- Vibration Parameters

- The vibration system's ability to produce frequencies from 5 Hz to

2000 Hz and amplitudes up to 50 mm allows for a thorough evaluation

of the passenger parts. Low-frequency vibrations can mimic the slow

oscillations caused by engine idling or driving on a bumpy road,

while high-frequency vibrations can replicate the rapid vibrations

associated with high-speed rotating components or electrical

switching. The precise control of vibration frequency and amplitude

is crucial for identifying potential resonance points and

weaknesses in the components.

|