In the realm of environmental laboratory testing, the need for

comprehensive and accurate simulations of real-world conditions has

become increasingly crucial. The customized Temperature and

Humidity Test Climatic Chamber with a Vibration Shaker is a

state-of-the-art apparatus that meets this demand with remarkable

precision and versatility. This advanced testing equipment is designed to create a controlled

environment that replicates a wide range of temperature, humidity,

and vibration scenarios. It serves various industries, including

aerospace, automotive, electronics, and telecommunications. The

primary purpose is to assess the performance and durability of

products and materials under the combined influence of these

environmental and mechanical factors. By subjecting test samples to

such complex conditions, manufacturers and researchers can identify

potential weaknesses, optimize designs, and ensure compliance with

industry standards and regulations. - Robust and Insulated Chamber Structure

- The climatic chamber is constructed with a heavy-duty steel frame

that provides exceptional rigidity and stability. The frame is

coated with a corrosion-resistant finish to enhance its longevity.

The chamber walls are made of high-quality insulation materials,

which minimize heat transfer and maintain precise temperature and

humidity levels. The insulation is carefully selected to withstand

the rigors of continuous testing and prevent any external factors

from interfering with the internal test environment. The chamber is

also equipped with a hermetic door seal, ensuring a leak-free

enclosure and consistent test conditions.

- Precision Temperature and Humidity Control System

- The chamber features a highly accurate temperature and humidity

control system. It can maintain a wide temperature range, from

-60°C to +180°C, with an accuracy of ±0.5°C. The humidity control

range extends from 10% to 98% relative humidity, with an accuracy

of ±2% RH. The system utilizes advanced refrigeration units,

electric heaters, humidifiers, and dehumidifiers to achieve and

maintain the desired environmental conditions. The temperature and

humidity sensors are strategically placed within the chamber to

provide real-time feedback, enabling the control system to make

rapid and precise adjustments.

- Powerful Vibration Shaker

- Integrated into the chamber is a high-performance vibration shaker.

It is capable of generating a wide range of vibration frequencies

and amplitudes. The frequency range can span from 2 Hz to 2000 Hz,

allowing for the simulation of various real-world vibration

sources, such as machinery operation, transportation, and seismic

activity. The vibration amplitude can be adjusted from a few

micrometers to several centimeters, depending on the test

requirements. The shaker is mounted on a vibration isolation

platform to prevent any external vibrations from affecting the test

results and to ensure the safety of the surrounding laboratory

environment.

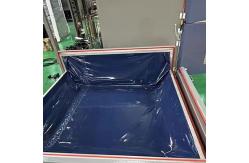

- Customizable Interior and Fixtures

- The chamber offers a customizable interior space to accommodate

different sizes and shapes of test samples. It can be equipped with

adjustable shelves, racks, and mounting fixtures, allowing for

flexible test setups. The interior surfaces are made of

non-corrosive and non-reactive materials to prevent any

contamination or interaction with the test samples. Additionally,

the chamber can be fitted with various accessories, such as cable

ports, viewing windows, and access doors, to facilitate testing and

monitoring.

- Advanced Control and Data Acquisition Interface

- The equipment is equipped with an intuitive control panel and a

sophisticated data acquisition system. The control panel allows

operators to easily set and adjust the temperature, humidity,

vibration parameters, and test durations. It provides real-time

display of the current test conditions and any alarms or warnings.

The data acquisition system records all relevant test data,

including temperature and humidity profiles, vibration waveforms,

and sample responses. The data can be stored in a built-in memory

or exported to external storage devices for further analysis. The

system also has the ability to generate detailed test reports in

various formats, such as PDF or Excel.

- Maximum Temperature Swing Rate

- The chamber can achieve a maximum temperature swing rate of 5°C per

minute. This rapid temperature change capability is essential for

simulating sudden environmental temperature fluctuations, such as

those experienced during rapid altitude changes in aerospace

applications or during the startup and shutdown of industrial

equipment. For example, in testing electronic components for an

aircraft, the ability to quickly change the temperature helps

evaluate their performance under extreme and dynamic thermal

conditions.

- Humidity Change Rate

- The humidity change rate can be adjusted up to 10% RH per minute.

This allows for the simulation of rapid humidity transitions, such

as those that occur when moving from a dry indoor environment to a

humid outdoor environment or vice versa. In the electronics

industry, this is crucial for testing the moisture resistance of

circuit boards and components, as high humidity can cause

condensation and lead to short circuits or corrosion.

- Maximum Vibration Acceleration

- The vibration shaker can produce a maximum vibration acceleration

of up to 100 m/s². This high acceleration level is sufficient to

replicate the intense vibrations experienced in heavy machinery,

high-speed transportation, and seismic events. For instance, in

testing automotive engine components, a significant vibration

acceleration can help assess their durability and resistance to

fatigue under extreme mechanical stress.

- Testing Volume and Payload Capacity

- The chamber offers a customizable testing volume, with options

ranging from 1 m³ to 20 m³. The payload capacity can be adjusted

according to the size and weight of the test samples, with a

maximum capacity of up to 2000 kg. This flexibility allows for the

testing of a wide variety of products, from small electronic

devices to large industrial machinery components.

- Vibration Shaker Displacement Range

- The vibration shaker has a displacement range of ±75 mm. This range

enables the simulation of both small, high-frequency vibrations and

large, low-frequency oscillations. It is particularly useful for

testing the performance of products with different resonant

frequencies, such as mechanical springs, shock absorbers, and

vibrating screens.

- Accurate Simulation of Environmental and Mechanical Conditions

|