In the automotive industry, the reliability and performance of

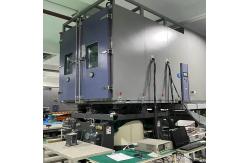

electrical components are of paramount importance. The HALT HASS

& AGREE Vibration Test Chambers, designed to meet GMW3172 for

electrical component testing, play a crucial role in ensuring that

these components can withstand the rigors of real-world operation

and deliver consistent functionality. This state-of-the-art vibration test chamber is dedicated to

subjecting automotive electrical components to a comprehensive

suite of tests in accordance with GMW3172. It serves automotive

manufacturers, Tier 1 suppliers, and research institutions. The

primary objective is to evaluate the durability and integrity of

electrical components such as sensors, connectors, control modules,

and wiring harnesses under various vibration and environmental

conditions. By simulating the harsh vibrations and stresses that

these components may encounter during a vehicle's lifespan,

manufacturers can identify potential weaknesses, optimize designs,

and enhance the overall quality and reliability of automotive

electrical systems. Robust and Shielded Chamber Structure The chamber is constructed with heavy-duty materials that provide

excellent protection against external electromagnetic interference.

The walls are made of conductive and ferromagnetic materials, which

act as a Faraday cage, shielding the internal testing environment

from stray electromagnetic fields. The interior is designed to

accommodate a wide variety of electrical components, with

adjustable racks and fixtures to ensure proper positioning and

secure mounting. The door is equipped with a reliable sealing

mechanism and a viewing window, allowing operators to monitor the

testing process without compromising the integrity of the shielded

environment.

Precision Vibration and Environmental Control Systems

Vibration System: Capable of generating a wide range of vibration

frequencies and amplitudes. It can produce vibrations from 5 Hz to

2000 Hz with amplitudes up to 50 mm. The vibration system is highly

precise, allowing for the programming of complex vibration profiles

to replicate different driving conditions, such as rough roads,

engine vibrations, and high-speed maneuvers. The vibration platform

is also designed to provide uniform vibration distribution across

the test samples, ensuring accurate and consistent testing results.

Temperature and Humidity Control: The chamber can maintain a wide

temperature range, typically from -40°C to +80°C,

with an accuracy of ±0.5°C. The humidity control

range extends from 10% to 95% relative humidity, with an accuracy

of ±3% RH. These environmental controls are essential as

temperature and humidity can significantly affect the performance

and reliability of electrical components. For example, high

humidity can cause corrosion and short circuits, while extreme

temperatures can lead to component failure or altered electrical

characteristics.

Intuitive Control Panel and Data Acquisition Interface

The control panel is user-friendly and allows operators to easily

set and adjust test parameters such as vibration frequency,

amplitude, temperature, humidity, and test duration. It provides

real-time displays of the current environmental conditions and

vibration status, as well as any alarms or warnings. The chamber is

integrated with a comprehensive data acquisition system that

records all relevant test data. This includes vibration waveforms,

temperature and humidity histories, and any observable changes in

the electrical performance of the components. The data can be

stored in a built-in memory or exported to external storage devices

for further analysis. The system can also generate detailed test

reports in various formats.

Safety Features and Alarms

Over-temperature, over-humidity, and over-vibration protection

systems are in place to prevent damage to the chamber and the test

samples. Emergency stop buttons are easily accessible. Alarms are

triggered for abnormal temperature fluctuations, humidity levels,

vibration malfunctions, or any other equipment failures. The

chamber is also equipped with proper ventilation and exhaust

systems to handle any potentially harmful gases or vapors that may

be generated during the testing process. Additionally, the

shielding of the chamber helps protect operators from any

electromagnetic radiation that may be emitted during testing.

Vibration Parameters

The ability to produce vibrations from 5 Hz to 2000 Hz with

amplitudes up to 50 mm allows for a comprehensive evaluation of

electrical components. Low-frequency vibrations can mimic the slow

oscillations caused by engine idling or driving on a bumpy road,

while high-frequency vibrations can replicate the rapid vibrations

associated with high-speed rotating components or electrical

switching. The precise control of vibration frequency and amplitude

is crucial for identifying potential resonance points and

weaknesses in the components.

Temperature and Humidity Ranges and Accuracies

The -40°C to +80°C temperature range with

±0.5°C accuracy and 10% to 95% RH humidity range

with ±3% RH accuracy provide a wide spectrum of

environmental conditions for testing. Electrical components must be

able to function reliably across different climates and operating

conditions. For instance, a sensor used in a vehicle's engine

compartment may experience high temperatures, while a component in

the interior may be subject to more moderate temperature and

humidity levels. The accurate control of these parameters ensures

that the test conditions are realistic and repeatable.

Testing Volume and Payload Capacity

The chamber offers a customizable testing volume, usually ranging

from 3 m³ to 15 m³, depending on the size and

quantity of electrical components to be tested. The payload

capacity is designed to handle a significant amount of components,

with a maximum capacity of up to several tons. This flexibility

allows for efficient testing of both individual components and

complex assemblies.

Data Sampling Frequency and Resolution

The data acquisition system samples data at a frequency of up to

1000 Hz. The vibration data has a resolution of 0.1 Hz and 0.1 mm

for frequency and amplitude respectively. The temperature data has

a resolution of 0.1°C, and the humidity data has a

resolution of 0.1% RH. This high-resolution and frequent sampling

enable the detection of even the slightest changes in the test

conditions and component performance, providing valuable insights

for analysis and improvement.

Accurate Simulation of Real-World Conditions

The chamber replicates the combined effects of vibration,

temperature, and humidity that automotive electrical components may

face during their service life. By subjecting the components to

these realistic conditions, manufacturers can ensure that they will

perform reliably in the field. For example, a connector that is

prone to loosening under vibration and temperature changes can be

identified and redesigned before it causes issues in a vehicle.

Product Design Optimization and Quality Control

Through a series of tests on different electrical component

prototypes, the data obtained from the chamber can be used to

optimize product designs. Engineers can analyze the performance of

various materials, geometries, and manufacturing techniques under

the combined stress of vibration, temperature, and humidity. The

chamber also serves as a critical tool for quality control,

ensuring that each production batch of components meets the

required standards. If a particular control module shows signs of

electrical instability during testing, the design or manufacturing

process can be adjusted to correct the issue.

Research and Development Support

In the field of automotive electrical component research and

development, the HALT HASS & AGREE Vibration Test Chambers

offer valuable insights. Researchers can use it to study the

fundamental properties of new materials and their interactions with

vibration, temperature, and hum

|