In the rapidly evolving electric vehicle (EV) industry, the

reliability and performance of battery cells, modules, and packs

are of utmost importance. The Custom Climate Chamber with Vibration

Test is a cutting-edge solution designed to meet the specific and

demanding requirements of testing EV battery components. This advanced chamber is dedicated to simulating a wide range of

environmental and mechanical conditions that EV cells, modules, and

packs may encounter during their lifespan. It serves EV

manufacturers, battery research institutions, and testing

laboratories. The primary objective is to evaluate the durability,

safety, and performance of these components under various

temperature, humidity, and vibration stresses. By replicating

real-world scenarios, manufacturers can identify potential

weaknesses, optimize battery designs, and ensure compliance with

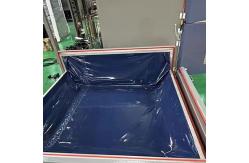

industry standards and safety regulations. - Robust and Insulated Chamber Structure

- The chamber is constructed with a heavy-duty steel frame and

insulated walls. The steel frame provides exceptional strength and

rigidity, ensuring the chamber can withstand the rigors of

continuous vibration testing. The insulation materials are

carefully selected to minimize heat transfer and maintain stable

temperature and humidity levels. The door is equipped with a

reliable sealing mechanism and a viewing window, allowing operators

to monitor the test process without disturbing the internal

environment. The interior of the chamber is designed with smooth,

easy-to-clean surfaces to prevent any particulate or contaminant

buildup that could affect the test results.

- Precision Temperature and Humidity Control System

- At the heart of the chamber lies a sophisticated temperature and

humidity control system. It can achieve a wide temperature range,

typically from -40°C to +80°C, with an accuracy of ±0.3°C. The

humidity control range extends from 10% to 95% relative humidity,

with an accuracy of ±2% RH. The system utilizes energy-efficient

refrigeration units, heaters, humidifiers, and dehumidifiers, all

coordinated by a precise PID controller. Multiple temperature and

humidity sensors are strategically placed throughout the chamber to

provide real-time feedback, enabling the control system to make

rapid and accurate adjustments.

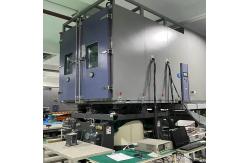

- Advanced Vibration Testing Capability

- The chamber is equipped with a state-of-the-art vibration testing

system. It can generate a wide range of vibration frequencies and

amplitudes, simulating the vibrations that occur during EV

operation, such as driving on rough roads or during acceleration

and deceleration. The vibration table is designed to provide

uniform vibration across the test samples, ensuring accurate and

reliable testing. The system can be programmed to replicate

specific driving profiles or industry-standard vibration tests,

allowing manufacturers to evaluate the effect of vibrations on the

integrity and performance of EV battery components.

- Intuitive Control Panel and Data Acquisition Interface

- The equipment is equipped with an intuitive control panel that

simplifies the operation and parameter setting. Operators can

easily adjust the temperature, humidity, vibration parameters, test

durations, and other settings using a user-friendly interface. The

control panel also provides real-time displays of the current

environmental conditions, vibration status, and any alarms or

warnings. The chamber is integrated with a comprehensive data

acquisition system. It records all relevant test data, including

temperature and humidity histories, vibration profiles, and any

observable changes in the test samples. The data can be stored in a

built-in memory or exported to external storage devices for further

analysis. The system can also generate detailed test reports in

various formats, facilitating easy documentation and sharing of

results.

- Safety Features and Alarms

- To ensure the safety of operators and the integrity of the testing

process, the chamber is equipped with a range of safety features.

These include over-temperature and over-current protection,

emergency stop buttons, and alarms for abnormal temperature

fluctuations, humidity levels, or vibration patterns. The safety

features are designed to prevent damage to the chamber, the test

samples, and the surrounding environment, providing peace of mind

during the testing operation.

- Temperature Range and Accuracy

- With a temperature range of -40°C to +80°C and an accuracy of

±0.3°C, the chamber can subject EV battery components to a wide

spectrum of temperatures. This is crucial for testing the

performance and durability of batteries in extreme cold and hot

conditions, such as during winter driving or in high-temperature

environments. The accurate temperature control ensures that the

test conditions are precisely maintained, providing reliable and

repeatable results.

- Humidity Range and Accuracy

- The humidity range of 10% to 95% RH, with an accuracy of ±2% RH,

allows for a comprehensive evaluation of the effect of moisture on

EV battery components. High humidity can affect the corrosion

resistance of battery terminals and the integrity of the battery

casing, while low humidity can cause drying and cracking of certain

materials. The ability to precisely control the humidity level is

essential for understanding how batteries respond to different

moisture environments.

- Vibration Parameters

- The vibration testing system can generate frequencies ranging from

5 Hz to 500 Hz and amplitudes up to 50 mm. These parameters can be

adjusted to simulate various driving conditions, from the gentle

vibrations of city driving to the more severe shocks and vibrations

of off-road or high-speed driving. The ability to accurately

control the vibration characteristics is vital for assessing the

durability and integrity of EV battery components and their

connections.

- Testing Volume and Payload Capacity

|