In the aerospace and defense sectors, where the margin for error is

infinitesimal, the Customized Climate Chamber with Vibration Test

emerges as a technological marvel. Engineered to meet the exacting

demands of these industries, it serves as a crucible for evaluating

the performance and reliability of components and systems under the

most extreme and realistic conditions. This state-of-the-art chamber is purpose-built to create and

control a highly customized climate environment while

simultaneously subjecting test specimens to precise vibration

stimuli. Tailored specifically for aerospace and Mil-Std defense

testing, it caters to manufacturers, research institutions, and

military organizations. The overarching objective is to replicate

the harsh and dynamic conditions that aerospace and defense

equipment encounter during their operational lifespan. This

includes simulating the extreme temperatures, humidity levels, and

rapid pressure changes experienced in high-altitude flight, as well

as the intense vibrations induced by rocket launches, missile

flights, and the rigors of military vehicle operations. By

subjecting products to such comprehensive testing, potential flaws

and weaknesses can be identified and rectified, ensuring that only

the most robust and reliable components make their way into the

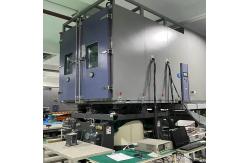

field. - Robust and Modular Construction

- The chamber is constructed with a heavy-duty framework, typically

made of high-strength alloys or carbon steel, to withstand the

substantial forces and stresses associated with vibration testing.

The modular design allows for easy customization and expansion,

enabling it to accommodate a wide variety of test specimen sizes

and configurations. The exterior is clad in a durable,

corrosion-resistant material, such as stainless steel or a

specialized aerospace-grade coating, to protect against the

elements and ensure long-term durability. The interior is lined

with a non-reactive and thermally efficient insulation material,

which not only helps maintain precise temperature and humidity

levels but also minimizes energy consumption. The door is

engineered with a high-precision sealing mechanism and a large,

impact-resistant viewing window, permitting operators to closely

monitor the testing process without compromising the integrity of

the internal environment.

- Precision Climate Control System

- At the core of the chamber's climate control capabilities is a

sophisticated temperature and humidity regulation system. It can

achieve an extensive temperature range, often spanning from -70°C

to +150°C, with an accuracy of ±0.5°C. The humidity control range

extends from 5% to 95% relative humidity, with an accuracy of ±3%

RH. This is made possible by a combination of high-capacity

refrigeration units, powerful heating elements, and advanced

humidification and dehumidification mechanisms. The system is

governed by a highly intelligent PID controller, which continuously

monitors and adjusts the climate parameters based on real-time

feedback from a network of strategically placed sensors throughout

the chamber. Additionally, the chamber can simulate rapid

temperature transitions and altitude-induced pressure changes,

replicating the extreme thermal and barometric conditions that

aerospace and defense equipment must endure.

- Advanced Vibration Testing System

- The vibration testing subsystem is a technological tour de force.

It is capable of generating a vast spectrum of vibration

frequencies and amplitudes, accurately mimicking the diverse

vibration profiles encountered in aerospace and defense

applications. The system can produce frequencies ranging from a few

hertz to several kilohertz and amplitudes up to several

millimeters. It employs a combination of electrodynamic shakers,

servo-hydraulic actuators, and precision control algorithms to

ensure that the vibration stimuli are precisely and consistently

applied to the test specimens. The vibration table is designed to

have minimal resonance and excellent force and displacement

accuracy, allowing for highly accurate and repeatable testing. The

system can also be programmed to execute complex vibration

sequences, such as random vibration profiles simulating the

turbulent flight conditions or shock pulses replicating the impact

of missile launches or hard landings.

- Intuitive Control and Data Acquisition Interface

- The chamber is equipped with an ergonomic and highly intuitive

control panel, which simplifies the operation and parameter setting

for even the most complex testing scenarios. Operators can

effortlessly configure the temperature, humidity, vibration

frequency, amplitude, test duration, and other critical parameters

using a user-friendly touchscreen interface. The control panel also

provides real-time visualizations of the current test conditions,

including temperature and humidity trends, vibration waveforms, and

any system alarms or warnings. Integrated within the chamber is a

comprehensive data acquisition system that records every aspect of

the testing process. It captures temperature and humidity

histories, vibration spectra, and any observable changes or

responses in the test specimens. The data can be stored in a

high-capacity internal memory or exported to external storage

devices for in-depth analysis. The system is also capable of

generating detailed test reports in various industry-standard

formats, facilitating seamless documentation and sharing of results

among different stakeholders.

- Safety and Monitoring Systems

- To safeguard both the testing equipment and the surrounding

environment, the chamber is outfitted with a comprehensive suite of

safety features. These include over-temperature and over-pressure

protection circuits, emergency stop buttons, and fail-safe

mechanisms that automatically shut down the system in the event of

a malfunction or abnormal condition. The vibration testing system

is equipped with overload protection and displacement limit sensors

to prevent damage to the shakers and the test specimens.

Additionally, the chamber is integrated with a continuous

monitoring system that tracks the health and performance of all

critical components, providing proactive alerts for preventive

maintenance and ensuring the long-term reliability and availability

of the testing facility.

- Temperature Range and Accuracy

- With a temperature range of -70°C to +150°C and an accuracy of

±0.5°C, the chamber can subject aerospace and defense components to

a wide gamut of thermal conditions. This is essential for testing

materials and systems that must function reliably in the extreme

cold of outer space or the intense heat generated during supersonic

flight or missile propulsion. The precise temperature control

ensures that the test conditions are accurately replicated,

yielding reliable and reproducible results.

- Humidity Range and Accuracy

- The humidity range of 5% to 95% RH, with an accuracy of ±3% RH,

allows for a comprehensive assessment of the impact of moisture on

the performance and durability of test specimens. In aerospace

applications, humidity can affect the integrity of electronic

components, the corrosion resistance of metals, and the

functionality of composite materials. The ability to precisely

control humidity levels enables manufacturers and researchers to

understand and mitigate these potential issues.

- Vibration Parameters

- The vibration testing system offers a frequency range from 2 Hz to

5000 Hz and amplitudes up to 50 mm. These parameters can be

adjusted in infinitesimal increments to create highly customized

vibration profiles. For example, in aerospace testing,

low-frequency vibrations may simulate the oscillations of a large

aircraft structure during flight, while high-frequency vibrations

can replicate the excitation of small components due to engine

vibrations or aerodynamic forces. The precise control over

vibration amplitudes and frequencies is crucial for accurately

assessing the fatigue life and mechanical integrity of test

specimens.

- Testing Volume and Payload Capacity

|