In the world of laboratory testing and product quality assurance,

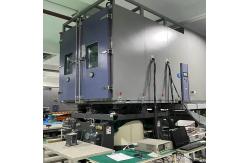

the Temperature Humidity Vibration Combined Climatic Test Chamber

is a powerful and indispensable tool. It is designed to subject

various specimens and products to a comprehensive range of

environmental conditions, simulating the real-world stresses they

might encounter during their lifecycle. The Temperature Humidity Vibration Combined Climatic Test Chamber

is a specialized apparatus used to conduct combined tests of

temperature, humidity, and vibration on a wide variety of samples.

It finds extensive application in industries such as electronics,

automotive, aerospace, and materials research. By precisely

controlling and varying temperature, humidity levels, and applying

vibration simultaneously or in sequence, it enables the evaluation

of how products or materials respond and perform under different

environmental stressors. This information is crucial for ensuring

the reliability, durability, and quality of products, helping

manufacturers to identify potential weaknesses and make

improvements before the products reach the market. - Robust and Controlled Testing Environment

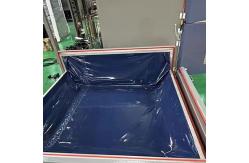

- The chamber is constructed from high-quality stainless steel or

other corrosion-resistant materials, ensuring its durability and

resistance to the harsh conditions within. It is engineered to

provide a highly sealed and insulated space, allowing for accurate

control of temperature and humidity. The interior is designed with

smooth surfaces to prevent any condensation or ice formation that

could affect the test results. The chamber is equipped with a

powerful refrigeration system, heating elements, and

humidification/dehumidification devices, all of which are precisely

calibrated and controlled by an advanced computerized control

system.

- The vibration system is a key component of the chamber. It

typically consists of an electromechanical shaker or a hydraulic

actuator that can generate a wide range of vibration frequencies

and amplitudes. The vibration table is mounted within the chamber

and is designed to have a high load-bearing capacity and excellent

vibration isolation to ensure that the vibrations are accurately

transmitted to the test sample without interference from external

sources.

- Precision Instrumentation and Measurement Capabilities

- The test chamber is fitted with a suite of high-precision sensors.

Temperature sensors with a high degree of accuracy and rapid

response time are used to monitor and control the temperature

within the chamber, typically with an accuracy of ±0.1°C. Humidity

sensors, often capacitive or resistive types, measure the relative

humidity levels with an accuracy of ±2% RH. The vibration sensors,

such as accelerometers, can accurately measure the vibration

amplitudes, frequencies, and acceleration levels applied to the

sample.

- The data acquisition system is capable of recording and storing all

the measured parameters in real-time. It can generate detailed

reports and graphs that provide a comprehensive analysis of the

sample's performance under the combined environmental stresses. The

control system allows for easy programming and setting of different

test profiles, enabling the simulation of complex environmental

scenarios.

- Flexible and Customizable Testing Modes

- The chamber offers a variety of testing modes. It can conduct

single-factor tests, such as only temperature cycling, humidity

exposure, or vibration testing, to isolate and study the effect of

each individual environmental factor. Additionally, it can perform

combined tests where temperature, humidity, and vibration are

applied simultaneously or in a specific sequence. For example, a

product might be subjected to a high-temperature and high-humidity

environment while being vibrated at a certain frequency, mimicking

the conditions it could face during transportation in a tropical

region. The testing parameters, including temperature range

(typically from -70°C to +150°C), humidity range (from 10% to 98%

RH), and vibration parameters (frequencies from 5 Hz to 2000 Hz and

amplitudes up to several millimeters), can be adjusted according to

the specific requirements of the test and the product being

evaluated.

| Product name | Temperature Humidity Vibration Combined Climatic Test Chamber | | Humi.Range | 10%Rh~98%Rh | | Computer Interface | RS-232c,USB | | Frequency Range | 1-3000Hz | | Control | Vibration,Cross-Temperature&Humidity | | Displacement | 100mm | | Rate Force | 2000kgf | | Temp. Range | 0°C -20°C -40°C -70°C~150 °C | | Temperature Falling Speed | 0.1~1.5°C/Min | | Temperature Rising Speed | 0.1~3.0°CMin | | Certification | ISO |

- Accurate Environmental Stress Evaluation

- The primary function of the Temperature Humidity Vibration Combined

Climatic Test Chamber is to provide a detailed and accurate

assessment of how products or materials respond to a combination of

environmental stresses. By precisely controlling and measuring

temperature, humidity, and vibration, it determines the effects on

the physical, chemical, and mechanical properties of the sample.

For instance, in the electronics industry, it can reveal if a

circuit board will experience solder joint failures or component

degradation under specific temperature and vibration conditions.

This helps manufacturers to optimize their product designs and

select more suitable materials to enhance durability.

- The measurement of various parameters during the test also aids in

understanding the failure mechanisms. It can identify whether a

material cracks due to thermal stress, corrodes in a humid

environment, or fails structurally under vibration. This knowledge

is invaluable for improving product quality and reliability.

- Compliance with Industry Standards and Regulations

- Many industries are subject to strict standards and regulations

regarding product quality and environmental testing. The test

chamber is a reliable tool for ensuring compliance. For example, in

the automotive industry, products must meet certain standards for

temperature and vibration resistance to ensure their performance

and safety during operation. By using this chamber to conduct tests

in accordance with relevant standards such as ISO, IEC, or

automotive-specific standards, manufacturers can prove that their

products meet the necessary requirements, facilitating market

access and enhancing consumer confidence.

- Regulatory bodies also rely on the accurate test results obtained

from this equipment to enforce safety and quality regulations. It

serves as a dependable means for inspectors and certifying agencies

to determine the suitability of products for use in different

applications.

- Research and Development Support

- In the field of research and development, the chamber is an

invaluable asset. It allows scientists and engineers to study the

effects of different environmental conditions on new materials and

product prototypes. For example, in the development of new

polymers, the chamber can be used to evaluate how changes in

temperature and humidity affect their mechanical properties and

durability. This helps in optimizing the formulation and processing

of materials to achieve better performance.

- The detailed data provided by the test chamber serves as a roadmap

for innovation. It enables researchers to explore new design

concepts and materials that can better withstand complex

environmental stresses, leading to the development of more advanced

and reliable products.

- Stringent Manufacturing Process

- The Temperature Humidity Vibration Combined Climatic Test Chamber

is manufactured under strict quality control procedures. Each

component, from the refrigeration unit to the vibration shaker and

the sensors, is carefully sourced and inspected for quality and

performance. The assembly process is carried out by highly trained

technicians in a clean and controlled environment, ensuring the

proper alignment and functionality of all parts.

- The calibration of the temperature, humidity, and vibration

measurement systems is a critical and regular part of the

manufacturing process. It is performed using traceable reference

standards to guarantee the accuracy and reproducibility of the test

results. Rigorous quality audits and inspections are conducted at

various stages of production to maintain the highest level of

product quality.

- Quality Certification and Validation

Our test chamber has obtained relevant quality certifications and

has been validated by independent testing laboratories. It has been

proven to provide accurate and reliable test results, conforming to

the relevant international and national standards. We also

continuously update and improve our product based on the latest

technological advancements and customer feedback to ensure its

long-term performance and compliance.

- Electronics Industry

- A leading electronics manufacturer used the Temperature Humidity

Vibration Combined Climatic Test Chamber to test a new generation

of smartphone components. The test results showed that a particular

type of connector had a tendency to loosen under a combination of

high temperature and vibration. By redesigning the connector and

using more suitable materials, they were able to improve the

product's reliability and reduce the number of field failures. The

company's reputation for quality was enhanced, and they gained a

competitive edge in the market.

- An electronics research institution utilized the chamber to study

the long-term stability of new semiconductor materials. The data

obtained helped them develop a new manufacturing process that

improved the material's resistance to environmental stress, leading

to the production of more durable and efficient semiconductors.

- Automotive Industry

- An automotive parts manufacturer used the test chamber to evaluate

the performance of a new engine control unit (ECU). The combined

environmental testing revealed that the ECU had issues with its

circuitry in a high-humidity and vibration environment. They were

able to make design changes and improve the sealing and component

layout, resulting in a more reliable ECU that met the strict

automotive industry standards.

- A major automotive manufacturer used the chamber to test the

durability of their vehicle interiors. By subjecting the materials

to temperature, humidity, and vibration cycles, they were able to

select more suitable fabrics and plastics that could withstand the

rigors of daily use and different climatic conditions, enhancing

customer satisfaction.

|