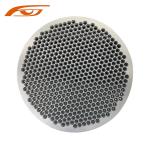

Control Custom Made 304 Steel CNC Machining Service with ISO9001 Certification

|

|

Technical Parameters(CNC Steel Parts)

Support and Services( Custom Steel CNC Machining Parts) Shenzhen Selection Hardware Technology Co., Ltd. is a trusted leader in providing one-stop CNC machining services tailored to meet the diverse needs of global industries. With over 17 years of manufacturing experience, state-of-the-art facilities, and a highly skilled team of engineers, we specialize in delivering high-precision CNC machined parts for industries such as automotive, electronics, aerospace, robotics, medical devices, and more. Our Comprehensive CNC Machining Capabilities 1. Advanced CNC Machining Equipment: We utilize cutting-edge 3-axis, 4-axis, and 5-axis CNC machining centers to achieve superior precision and meet tight tolerances as low as ±0.01mm. Our facilities are equipped to handle a wide range of materials, including metals (aluminum, stainless steel, brass, titanium, etc.) and plastics (POM, ABS, PC, nylon, etc.). 2. Full Range of CNC Services: CNC Milling: Ideal for complex shapes and high-precision components with tight tolerances. CNC Turning: Perfect for cylindrical parts, including shafts, bushings, and pulleys, with smooth surface finishes. Drilling, Tapping, and Threading: Accurate creation of holes and threads to meet your product requirements. Prototype to Mass Production: From small-batch prototypes to large-scale production runs, we have the capacity to meet all order sizes efficiently. 3. Surface Finishing Options: To enhance functionality and appearance, we offer a variety of surface treatments, including anodizing, polishing, sandblasting, powder coating, electroplating, and more. These finishes provide corrosion resistance, aesthetic appeal, and extended product durability. 4. One-Stop Solution from Design to Delivery: Design Support: Our experienced engineering team assists in optimizing designs for manufacturability, ensuring efficiency and cost-effectiveness. Material Sourcing: We procure high-quality raw materials from trusted suppliers to ensure durability and performance. Assembly Services: In addition to manufacturing individual parts, we provide assembly services, delivering fully assembled and tested components. Quality Control: Rigorous inspection processes, including CMM (Coordinate Measuring Machine) and other advanced measuring tools, ensure all parts meet customer specifications. Packaging and Shipping: Secure packaging and reliable global shipping ensure your parts arrive in perfect condition, ready for use.

Our Company and Factory(CNC Machining Steel Service) Shenzhen Selection Hardware-Tech Limited was established in 2007, rooted in Guangming District, Shenzhen. It has been deeply engaged in the field of precision manufacturing for 17 years and is dedicated to providing one-stop solutions for die-casting and CNC machining for global customers. Since 2013, we have continuously expanded the international market. With reliable product quality and efficient services, we have become a trusted partner in the global industrial supply chain. Core advantages: Integrated manufacturing, fully controllable throughout the

process Die casting factory: Specializing in die-casting of aluminum alloys and zinc alloys, integrating precision mold development with automated production technology, it meets the demands for high-strength components in fields such as automobiles, electronics, and industrial equipment. CNC machining factory: Equipped with over 70 advanced CNC machines, it includes 5-axis linkage machining centers, precision milling and turning workshops. It can handle various materials such as stainless steel, aluminum alloy, titanium alloy, and copper. It excels in customized production of complex structural parts and high-precision components, and supports diverse surface treatment processes such as oxidation, electroplating, and sandblasting. Technology-driven, quality-assured Self-designed, mold-making, processing and assembly, seamless connection of each link, shortening the delivery time. Strict quality inspection procedures (IQC/IPQC/OQC), equipped with testing equipment such as three-coordinate measuring instruments and spectrometers, with an accuracy of ±0.01mm; Flexibly respond to customer demands, support small-scale trial production to large-scale mass production, and cover multiple industry application scenarios such as industrial equipment, new energy, and consumer electronics. Mission and Commitment

1. Solving Industry Pain Points ❌ Your Challenges: - Traditional workshops fail to deliver complex geometries and

tight tolerances? - High costs and slow turnaround for small-batch customization? - Material selection dilemmas causing part failures or budget

overruns? ✅ Our Solutions: - “Complexity Mastered" Technology**: 5-axis machining + dynamic

milling for impellers, helical grooves, and intricate parts. - "1-Piece MOQ" Flexible Production: No mold fees, pay-per-part

pricing for prototypes and small batches. - Material Service: Free expert guidance to balance performance,

cost, and machinability. -2. Service Highlights (Differentiated Value) ✨ "Zero Communication Gaps": - **Free Design Optimization**: Automatically fix issues like

thin-wall deformation or tool interference. - Real-Time Order Tracking: Regular progress updates and machining

videos sent to your email. ✨ "Zero Inventory Pressure": - Rush Orders Guaranteed: 20% machines reserved for 72-hour urgent

deliveries. - On-Demand Shipping: Split deliveries and warehousing support to

reduce your stockpile.

Our Advantages for Custom Steel CNC Milling Machining Parts ☛ ISO9001:2015 Self-Operated Factories, with 17 years'

manufacturing experience |

||||||||

| Product Tags: CNC Machining Service ISO9001 304 Steel CNC Machining Custom Made Steel CNC Machining |

|

ISO 2768 MK Tolerance Steel CNC Milling Parts for Durable and Long-lasting Machining |

|

Control Custom Made 304 Steel CNC Machining Service with ISO9001 Certification |

|

Custom Stainless Steel Fastener Precision Termostatic Cap CNC Machining Services for Auto Processing Types |

|

Shenzhen Custom Metal Steel 304 316 CNC Milling Parts CNC Machining Services |

|

OEM High Demand Steel 4140 Metal Steel CNC Milling Services CNC Milling Steel Parts |

|

Heat Resistance Cnc Milling Parts Stainless Steel Fabrication Service Wear Resistance |