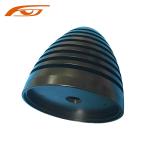

Black Custom Painting Service Powder Coated Sandblasting Cnc Machining Service

|

|

Custom Painting Parts Painting Service Powder Coated Sandblasting Cnc Machining Service

Technical Parameters

Custom Painting Parts Painting is a widely used surface finishing process where a layer of paint is applied to the surface of an object to protect it, improve its appearance, or provide specific functional benefits (such as corrosion resistance, color coding, or a smooth finish). The painting process involves applying a coating of pigment and binder materials, which may include solvents or other additives, to form a uniform and durable layer on the substrate.

Support and Services We have our own painting factory. Our company offer a series of painting surface treatments, such as painting, sandblasting, powder coating. Painting provides a highly customizable and functional surface finish that can enhance the appearance, protect the substrate, and improve performance for a wide variety of applications. Therefore, the painting parts we manufactured are high quality. At Shenzhen Selection Hardware Technology Co., Ltd., we pride ourselves on delivering high-quality custom painting solutions that meet diverse industry needs.

Our Painting Process 1. Surface Preparation We ensure a clean and smooth surface by performing pre-treatment processes such as sandblasting, polishing, or anodizing (if required). 2. Painting Application We use advanced automated spraying systems and high-precision manual techniques to ensure a uniform and flawless finish. 3. Drying & Curing Our controlled drying and curing process guarantees that the coating bonds well with the surface, ensuring long-lasting durability. 4. Final Inspection Each painted part undergoes thorough quality inspection to ensure consistent finish, color accuracy, and coating adhesion.

Why Choose Us? 1. Advanced Equipment & Technology We utilize state-of-the-art painting booths and automated spraying systems to ensure consistent, even coatings and superior finishes. Our facilities are designed to handle both small and large production volumes efficiently. 2. Wide Range of Coating Options We offer a variety of painting solutions, including: Powder Coating for durability and environmental friendliness Spray Painting for smooth, uniform finishes Custom Colors to match specific brand or product requirements Special Coatings such as anti-corrosion, heat-resistant, and UV-protective coatings 3. High-Quality Surface Finish Our painting process enhances the appearance and performance of your parts, providing: Smooth and flawless surfaces Scratch-resistant and long-lasting finishes Precise color matching for a professional look 4. Strict Quality Control We implement rigorous quality control measures at every stage of the process, ensuring: Consistent thickness of coatings No defects such as bubbles or peeling Adherence to international standards, including ISO 9001:2015 certification 5. Industry Expertise With over 17 years of experience in surface finishing and manufacturing, we have served clients across various industries, including Automotive, Electronics, Medical Devices and Aerospace. 6. Customization & Flexibility We can tailor our painting services to meet your unique requirements, whether you need: Small-batch prototypes High-volume production Complex part geometries 7. Comprehensive One-Stop Service In addition to painting, we offer a full range of complementary services, including CNC Machining, Die Casting, Sheet Metal Fabrication and Assembly & Packaging. This integrated approach saves you time and reduces costs. 8. Global Clientele & Proven Track Record We’ve partnered with renowned brands such as RODE, Rolls-Royce, and BYD, providing reliable painting solutions that meet international standards. 9. Competitive Pricing Our efficient processes and advanced technology enable us to offer high-quality painting services at competitive prices, ensuring the best value for your investment.

FAQ Q1: Are you trade company or manufacturer? A1: We are professional manufacturer with over 17 years' experience, we have self-operated factories, welcome to visit our factories.

Q2:Do you offer OEM or ODM business? A2: Yes. OEM and ODM are our main business.

Q3:What services do your company offer? A3: One-stop metal/plastic fabrication service. Main processing: cnc machining, die casting, investment casting, sheet metal fabricaiton, injection molding.

Q4: Can you help assembling the parts after it is manufactured? A4: Yes. Our factory has multiple assembling lines.

Q5: What is the price of our product? A5: The price is depend on your projects. Typically, our prices are competitive.

Q6: What is the delivery time? A6: Usually 7~15 working days for sample, 30 working days for mass production.

Q7: Will my drawing or other documents be safe after you get it? A7: Yes. We can sign confidential aggrement for all your projects |

||||||||||||||||||||||

| Product Tags: Custom Painting Service Powder Coated Sandblasting Cnc Machining Service Powder Coated Cnc Machining Service |

|

OEM Design One Stop Custom Painting Service Precision Die Casting Parts |

|

Cnc Machining Components Investment Die Casting Process Black Painting Coated |

|

Oem Precision Cnc Casting Parts Custom Painting Coated Fabrication Service |

|

Black Custom Painting Service Powder Coated Sandblasting Cnc Machining Service |

|

Custom Painting Service Cnc Machining Milled Metal Parts Powder Coating |