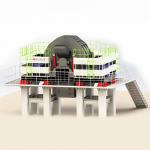

High Capacity and Customizable Horizontal Shaft Impactor Crusher

for Mining Industry

Product Description:

The Horizontal Shaft Impactor Crusher is perfect for those in the

construction industry or mining industry who need to break down

large rocks quickly and efficiently.

The Horizontal Shaft Impactor Crusher is a reliable and efficient

machine that is perfect for any construction or mining project. Its

powerful impact crushing capabilities make it an excellent choice

for breaking down large rocks and hard materials. So, if you're

looking for a reliable and durable crusher, the Horizontal Shaft

Impactor Crusher is the perfect choice.

Applications:

Product Upgrades:

- Addition of a shock absorption system

- Enlargement of the crushing chamber

- Automatic lubrication system

Widely applicable for crushing and artificial sand making of

materials such as river pebbles, basalt, granite, quartz, metallic

ores, and non-metallic ores.

Key Features and Advantages (HSI vs VSI):

- Energy Savings: Reduces electricity consumption by 40–50%.

- Lower Consumable Costs: Saves 10–20% on wear part expenses.

- Larger Feed Size: Handles larger feed sizes and doubles the sand formation rate.

Additionally, for river pebble sand (~10mm), sand production

remains unaffected.

- Extended Wear Part Lifespan: The replacement cycle for throwing heads is extended by 5–7 times,

significantly improving continuous production cycles.

- High-Quality Shaping: Manufactured sand and crushed stone meet high standards for

aggregate quality.

- Ease of Use and Maintenance: Simple operation, easy maintenance, lower costs, and quick

replacement of wear parts.

- Portable Installation: Can be installed on a ship for mobility.

- High Cost-Performance Ratio: Low investment, quick returns, and excellent value.

Technical Parameters:

| Model | Max. feed size(mm) | Capacity(t/h) | Product size(mm) | Output(t/h) | Motor power(kw) | Dimensions(mm) |

| PW2006 | ≤70 | 40-50 | 0-5mm | 25-30 | 90 | 360x150x207 |

| 5-31.5mm | 10-15 |

| PW2008 | ≤80 | 60-80 | 0-5mm | 40-55 | 160 | 362x191x210 |

| 5-31.5mm | 15-20 |

| PW3008 | ≤90 | 90-110 | 0-5mm | 55-65 | 250 | 385x242x255 |

| 5-31.5mm | 20-30 |

| PW3308 | ≤100 | 120-140 | 0-5mm | 70-90 | 315 | 432x296x266 |

| 5-31.5mm | 30-40 |

| PW3608 | ≤100 | 160-200 | 0-5mm | 110-130 | 400 | 518x318x312 |

| 5-31.5mm | 30-40 |

| PW4010 | ≤100 | 300-400 | 0-5mm | 200-250 | 2x315(400) | 704x418x370 |

| 5-31.5mm | 60-80 |

FAQ for customers to get a correct offer:

1.What type of stone needs to be crushed? Soft rock or hard rock?

2.What is the required output of the manufactured sand? 100t/h?

300t/h?

3.What is the maximum size of the stone particles? 70 cm? 50 cm?

4.How many size specifications are needed for the manufactured

sand?

Customer's Producing Line: