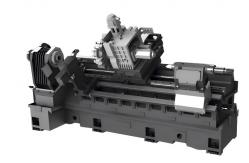

Torno Automatic Universal CNC Turning And Milling Center With Dual Spindle

|

Detailed Product Description

|

Taiwan cnc torno automatico lathe machine center fresadora

universal de servicio pesado metal lathes Torno Automatic Universal CNC Turning And Milling Center With Dual

Spindle Taiwan cnc torno automatico lathe machine center fresadora

universal de servicio pesado metal lathes Description Tailored Solutions for High-Volume Production To address your high-volume production needs, we offer a high-travel turning and milling composite CNC lathe with an inclined bed for optimal chip clearance. The W7-based model comes with extended travel and swing diameters of 1 meter, 1.5 meters, 2 meters, and 3 meters. You can further customize your machine by adding a Y-axis for complex machining tasks and center supports for improved stability. Additionally, larger spindle options are available to enhance productivity and accommodate different workpiece sizes. Specification

Other information

Recommend Products Products Description Details Display The machine's transmission system employs high-precision ball screws and high-rigidity,high-speed roller guides. The X-axis and Z-axis feature high-rigidity linear slides with

anoptimally calculated track span,offering low

resistance,highprecision,and speeds up to 22m/min.This enhances

workefficiency and reduces processing time. The Driven Tool Turret can perform various machining operations such as drilling,milling,and tapping,which meansthat a

single machine can complete more types of tasks,enhancing the flexibility and range of the machine.Overall,thelathe

Driven Tool Turret significantly improves the efficiencyand quality

of lathe machining by providing multi-functionalmachining

capabilities,quick tool changes,high precision,andautomated

operations.It is an indispensable and importantcomponent in modern

precision manufacturing. Our CNC turret lathes are equipped with avariety of

mechanicalspindles to choose from.These spindles are notable for

theirhigh rigidity,minimal noise and

vibration,and,crucially,theirability to perform high-precision

operations.The precisionof movement and the robustness of the

spindle componentsplay a pivotal role in defining the quality of

processing and theefficiency of cutting operations. NSK super-precision bearings,featuring high running accuracy,rapid speed capabilities,and exceptional precision,are ideallysuited for spindle units in machine tools.These bearings arespecifically engineered to reduce noise,vibration,and heatgeneration,enhancing overall performance. In addition,the eletric spindle can be selected.The advantagesof an electric spindle include high speed,high precision,widerange of speed variation,high rigidity,precise control,energysaving and environmental protection,and low maintenancecosts.Overall,the machine tool electric spindle has significantadvantages in improving processing efficiency,precision,and quality,and therefore,it is widely used in modernmanufacturing. Equipment Display |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Automatic CNC Turning And Milling Center Automatic cnc vertical lathe Universal CNC Turning And Milling Center | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Related Products

Email to this supplier