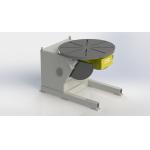

The handling of large weldments and parts can be done safely by the

use of positioning equipment.

Our poitioners are designed to position even the heaviest and most

unwieldy cylindrical workpieces, making welding and fabrication a

breeze.

Positioners reduce workload on overhead cranes and other handling

equipment.Welders like working with these welding positioners as

they can position their workpieces at the ideal working height and

rotate them at the desired speed while welding. Welds are done more

efficiently and defects are reduced. Based on the form of

positioning, they can be divided into several categories, such as

L-type, horizontal turntable, headstock and tailstock, etc., with

loading capacities ranging from 100kg to 300 tons.

DIG Benefits

Precision: Improves the accuracy of welds by allowing precise

positioning and control over the workpiece.

Productivity: Optimisation of production processes. Reduces the

time and effort required to manually reposition workpieces,

speeding up the welding process. Moreover, depending on actual

needs, we can provide different types of welding positioners that

can be integrated with various execution devices including robots,

column and booms, welding gantries and etc., in order to complete

the synthesis of complex paths.

Safety: Improved occupational safety. Minimizes the need for manual

handling of heavy parts, reducing the risk of injury.

Quality: Reduction of wire and gas usage. Ensures uniform welds by

maintaining optimal positioning throughout the welding process.

| Category | Standard Load |

| RTP | 5 | 10 | 20 | 30 | 50 | 80 | 100 | 150 | 200 | 250 |

| HTP | 3 | 5 | 10 | 15 | 20 | 30 | 40 | | | |

| LTP | 0.5 | 1 | 2 | 3 | 5 | 10 | | | | |

| OTP | 1 | 2 | 3 | 5 | 10 | 20 | 30 | | | |