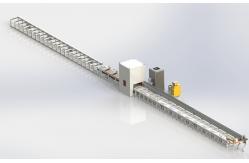

The profile cutting line is a fast and reliable steel profiling

solution for your shipyard.

This efficient system is specifically configured to handle profiles

such as bulb, angle bar, flat bar, and T bar, ensuring optimal

processing and quality control throughout the manufacturing

process. Any 3D shape can be accurately cut with the robot plasma

cutter. With the ability to stack profiles of different sizes on

the infeed and roll them in as needed, material handling has been

greatly reduced, along with the required manpower. DIG’s profile

cutting line combines precision plasma cutting with the digitised

production at an exceptional level, and the corresponding hardware

and software interfaces can be interconnected with the MES system

of the workshop to realize unified management of the data in the

whole production process. Work plan allocation and task list

tracking will bring unprecedented convenience to production.

A Set of Various Workstations

The Profile Cutting Line consists of the following workstations:

1. Profile Storage Warehouse

2. Profile Straightening Machines

3. Profile Edge Milling Machine

4. Profile Edge Shot Blasting

5. Profile Cutting Machine

6. Profile Sorting System

DIG Benefits

Precision and Accuracy: The robot is laser calibrated, which gives

it unmatched accuracy for any 3D shape. Ensures precise cutting of

profiles, meeting tight tolerances and specifications.

Efficiency: One click operation can complete autonomous cutting.

Reduces material waste and reliance on professional skills of

workers.

Productivity: Increases throughput with continuous operation and

minimized downtime. More accurate cuts result in better fitting

parts and less rework.

Quality Assurance: Consistent quality control measures throughout

the cutting and processing stages.

Improving work safety and reducing unnecessary production accidents