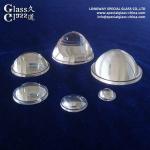

High Transparent Borosilicate Glass Explosion-proof LED Lens For

Hazardous Areas Material- Borosilicate Glass:

- Composed primarily of boron trioxide and silicon dioxide, with a

small percentage of other oxides for enhanced properties.

- Known for its high thermal shock resistance, low coefficient of

thermal expansion, and excellent chemical stability.

Property- High Transparency:

- Offers excellent light transmission, minimizing light loss and

enhancing the brightness and efficiency of LED lights.

- Explosion-proof:

- Designed to withstand high pressures and temperatures, preventing

shattering or explosion in hazardous environments.

- Chemical Resistance:

- Resistant to attack by acids, alkalis, and other corrosive

substances, ensuring long-term durability in harsh conditions.

- Thermal Stability:

- Can withstand extreme temperature fluctuations without cracking or

deforming, maintaining optical clarity and performance.

Function- Protective Lens:

- Acts as a protective barrier between the LED light source and the

hazardous environment, preventing damage to the light and ensuring

operator safety.

- Optical Clarity:

- Ensures that the LED light is transmitted clearly, without

distortion or scattering, enhancing visibility and illumination in

the area.

- Explosion Mitigation:

- In the event of an explosion or extreme pressure build-up, the lens

is designed to contain the blast, reducing the risk of injury and

damage to surrounding equipment.

Application- Hazardous Areas:

- Specifically designed for use in environments where explosives or

flammable materials are present, such as chemical plants, oil rigs,

and mining operations.

- Industrial Lighting:

- Ideal for high-bay lighting, explosion-proof fixtures, and other

industrial lighting applications where safety and reliability are

paramount.

- Outdoor and Marine Use:

- Suitable for outdoor installations in extreme climates and marine

environments, where resistance to corrosion and temperature

variations is crucial.

| Name | glass led lens or glass cover | | Material | Pyrex, borosilicate glass 3.3 | | Diameter Tolerance | +0/-0.2 mm | | Thickness Tolerance | +/-0.2 mm | | Processed | by molding, grinding, polishing | | Working temperature | resisting high temperature shock | | Surface Quality | Optical grade | | Material Quality | no scratches and air bubble | | Transmission | above 90% | | Chamfer | 0.1-0.3 mm x 45 degree | | Surface Coating | Available | | Usage | Lighting system,Electronic apparatus |

|