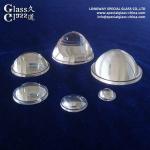

Custom Borosilicate Glass Beam-shaping LED lens for specialty

lighting effects

1. Core Material: Borosilicate Glass High-Performance Glass: Specifically chosen for its exceptional thermal and chemical

properties. Key Attributes: Extremely low thermal expansion coefficient, high thermal

shock resistance, excellent chemical durability, and inherent

optical clarity. Critical for LEDs: Withstands intense heat generated by high-power LEDs without

degrading or cracking, unlike standard glass or many plastics.

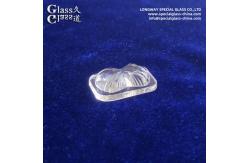

2. Defining Property: Precision Beam-shaping Optical Engineering: The lens is meticulously designed (often using optical software)

and manufactured to manipulate light rays with high accuracy. Function Types: Can act as a collimator (creates narrow beams), diffuser

(spreads light evenly), TIR (Total Internal Reflection) optic

(efficiently collects and directs light), or create specific

patterns (gobos, ellipses, asymmetric distributions). Surface Accuracy: Custom molding achieves complex, freeform surfaces critical

for precise optical control.

3. Primary Function: Creating Specialty Lighting Effects Controlled Light Distribution: Shapes the raw output of an LED into a specific, desired beam

pattern or intensity profile. Enhanced Effects: Enables dramatic, focused, patterned, or textured lighting

impossible with standard reflectors or diffusers. Efficiency: Minimizes light spill and maximizes usable light output in

the desired direction/form.

4. Key Feature: Custom Molding Bespoke Design: Manufactured to exact specifications (size, curvature, focal

length, surface profile) dictated by the unique lighting effect

required. Complex Geometries: Enables intricate shapes (aspheric, faceted, stepped) essential for

advanced beam control, unachievable with simple off-the-shelf

lenses. Consistency: Ensures precise optical performance and perfect fit within custom

luminaires.

5. Target Applications: Entertainment & Stage Lighting: Spotlights, moving heads, profile lights for precise beam control,

gobo projection, sharp cutoffs. Architectural Highlighting: Precise accent lighting for artwork, sculptures, façades, or retail

displays. Museum & Gallery Lighting: Controlled, low-UV lighting to illuminate artifacts without damage

or glare. Specialized Industrial: Machine vision lighting, scientific instrumentation, medical

devices requiring specific illumination patterns. High-End Retail & Hospitality: Creating unique ambient or focal lighting effects for

atmosphere.

6. Key Benefits: Superior Optical Performance: Unmatched clarity, minimal scatter, precise beam control. Extreme Durability: Resists thermal shock, chemicals, and physical wear for long

lifespan. High-Temperature Stability: Maintains shape and clarity under intense LED heat. Design Freedom: Enables innovative luminaire designs with unique lighting effects. Consistency & Reliability: Essential for professional, repeatable results.

In essence: This lens combines the thermal resilience and optical

purity of borosilicate glass with advanced custom molding to create

highly precise optical components. It transforms raw LED light into

specialized, controlled beams and effects, making it indispensable

for professional, architectural, and high-performance specialty

lighting applications demanding both reliability and dramatic

visual impact.

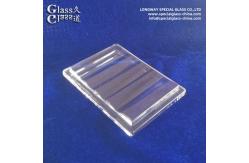

| Name | glass lens or glass cover | | Material | Pyrex, borosilicate glass 3.3 | | Diameter Tolerance | +0/-0.2 mm | | Thickness Tolerance | +/-0.2 mm | | Processed | by molding, grinding, polishing | | Working temperature | resisting high temperature shock | | Surface Quality | Optical grade | | Transmission | above 90% | | Chamfer | 0.1-0.3 mm x 45 degree | | Usage | Lighting system,Electronic apparatus |

|