Tempered Borosilicate Level Gauge Sight Glass for High-Temp

Industrial Tanks

Material Composition Primary Material: Borosilicate glass (commonly Borosilicate 3.3 per ISO 3585

standards). Tempering Process: Chemically or thermally strengthened to enhance durability. Key Additives: Silicon dioxide (80-85%), boron trioxide (10-13%), and trace

alkaline earth metals.

Key Properties Thermal Resistance: Withstands temperatures up to 450°C (842°F) and thermal shocks from ΔT 160–200°C. Mechanical Strength: Tempering increases impact resistance (4–5x stronger than

annealed glass). Chemical Durability: Resists corrosion from acids, alkalis, and solvents (pH 0–14). Optical Clarity: Maintains transparency under extreme conditions for accurate

visual monitoring.

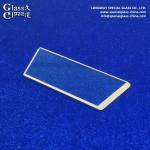

Primary Function Level Monitoring: Provides a clear visual interface to inspect liquid/gas levels in

high-temperature industrial tanks. Pressure Tolerance: Operates safely in systems with pressures up to 10–15 bar (varies by thickness). Safety Barrier: Acts as a leak-proof window, isolating internal tank conditions

from external environments.

Applications Chemical Processing Tanks: For aggressive acids, molten salts, or hot solvents. Power Generation: Boilers, steam systems, and thermal oil reservoirs. Oil & Gas: Refinery storage tanks, high-temp reactors, and LNG processing. Pharmaceuticals: Sterilization autoclaves and reactors requiring hygienic

visibility.

Advantages Over Alternatives Longevity: Outlasts soda-lime glass or polycarbonate in cyclic thermal

environments. Safety: Tempered design minimizes fragmentation risks if damaged. Low Maintenance: Resists clouding, scaling, or chemical etching.

Industry Standards

| Item | Glass disc, Glass wafer, Glass substrate, Sight glass | | Material | borosilicate glass, Float glass, borofloat | | Diameter Tolerance | +0/-0.2 mm | | Thickness Tolerance | +/-0.2 mm | | Processed | By Cutting,Grinding,Tempering, Polishing | | Working temperature | Resisting high temperature shock | | Surface Quality | 80/50,60/40 | | Material Quality | No scratches and air bubble | | Transmission | >90% for visible light | | Chamfer | 0.1-0.3 mm x 45 degree | | Surface Coating | Available | | Usage | Photography, Optics, Lighting system, industrial area. |

|